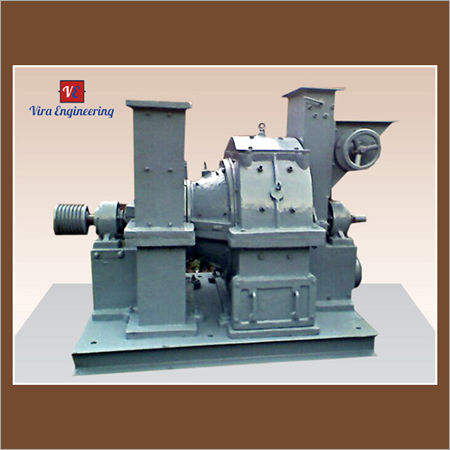

Grinding Pulverizer

Grinding Pulverizer Specification

- Model

- Standard Industrial

- Rotation

- Clockwise

- Product Type

- Grinding Pulverizer

- General Use

- Industrial grinding and pulverizing of materials

- Material

- Cast Iron & Steel

- Type

- Surface Grinding Machine

- Capacity

- 15-50 kg/h

- Weight (kg)

- Approx. 210 kg

- Computerized

- No

- Automatic

- Semi-automatic

- CNC Or Not

- Not CNC

- Control System

- Manual control

- Table Size

- 400 x 150 mm

- Table Slide Way

- Precision ground slideways

- Magnetic Chuck Size

- 300 x 150 mm

- Grinding Wheel Size

- 200 x 22 x 31 mm

- Grinding Wheel Speed

- 2800 RPM

- Grinding Length

- 200 mm

- Floor Space

- 700 x 900 mm

- Spindle Speed

- 2800 RPM

- Power

- 2 HP

- Voltage

- 220/440 V

- Dimension (L*W*H)

- 950 x 850 x 1350 mm

- Feature

- Robust construction, easy operation, high durability

- Color

- Blue or as per requirement

- Packaging Type

- Wooden box or as per request

- Safety Features

- Overload protection

- Cooling System

- Air cooled

- Maintenance

- Easy to maintain

- Blade Material

- Alloy steel

- Finish

- Powder coated

- Working Speed

- Variable, adjustable

- Installation

- Floor mounted

- Application

- Spices, minerals, chemicals, grains, and more

- Feed Size

- Up to 15 mm

- Motor Type

- Three phase induction motor

- Noise Level

- Low noise operation

Grinding Pulverizer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Grinding Pulverizer

The Pulverizer offered by us meets most capacity requirements. It changes to a wide degree of adjustment with the finesse of finished products. It is a grinding unit of heavy construction and build for continuous operation day by day. Moreover, it is specially designed for medium fine, and fine size reduction. The Pulverizer consists of various components like encased rotor carrying swing hammers, whizzer classifier for fineness regulation and pressure gradient creator mounted on a solid shaft.

The Impact Pulverizer Consists Of An Encased Rotor Carrying Swing Hammers, Whizzer Classifier For Fineness Regulation And Pressure Gradient Creator Mounted On A Solid Shaft. Raw Material To Be Pulverized Enters The Crushing Chamber Through The Hopper Or The Automatic Rotary Feeder. The Impact Of The Hammers On The Feed Material Against The Liner Plates Reduces It Into Fine Powder. The Ground Material Is Carried Towards The Whizzer Classifier For Classification And The Oversize Particles Are Rejected By The Classifier And Returned To The Crushing Chamber For Further Grinding. The Classified Material Is Then Conveyed Into The Cyclone For Collection And Bagging. A Dust Collector Is Provided In The System For Ensuring Dust Less Operation And For No Loss Of Ground Powder.

The Vira Engineering Impact Pulverizers Are Used For A Wide Range Of Application E.G. Agricultural, Chemicals, Carbon And Graphite, Coal, Coke, Coconut Shell And Wood Saw Dust, Clay, Dye Stuff And Pigments, Detergents, Ferro-Alloys Fertilizers, Fillers, Food Products, Herbs And Spices, Pesticides, Minerals, Plastics, Pharmaceuticals, Resins, Etc.

Advantages

- High Speed Rotor Assembly Two-Way Reversible Hammers / Beater

- Easy Access To Impact Pulverizers Interior Through Dual Access Doors

- Available In Different Size And Models

- Cold And Silent Running Dust Free Operations

- Robust Construction

- Low Specific Power Consumption

- Durable Long Life

- Guaranteed Grinding Efficiency, Particle Sizes Are Finer And More Uniform Than That Obtained From Machine Using Screen

Product details

| Frequency [Hz] | 60Hz |

| Machine Type | Pulverizer Machine |

| Material Grade | SS304 |

| Country of Origin | Made in India |

| Automation Grade | Semi-Automatic |

| Material | Stainless Steel |

| Brand | Vira Engineering |

| Color | Grey |

| Finishing | Color Coated |

| Driven Type | Electric |

| Corrosion Resistance | Yes |

| Voltage | 440V |

| Machine Capacity | 200kg/hr |

| Phase | Three Phase |

Exceptional Grinding Performance

Designed for industrial use, this surface grinding machine delivers consistently fine results across a wide range of materials, including spices, minerals, chemicals, and grains. With a variable and adjustable working speed, precision ground slideways, and a robust blade made from alloy steel, the pulverizer ensures high durability and efficient material processing.

User-Friendly Operation and Maintenance

The manual control system provides intuitive operation, while features such as overload protection and an air-cooled cooling mechanism contribute to safety and smooth running. The sturdy, powder-coated body and straightforward component access make routine maintenance easy, supporting uninterrupted operation and reducing downtime.

Adaptable and Safe Industrial Solution

Floor-mounted for maximum stability, the grinding pulverizer accommodates feed sizes up to 15 mm and is designed with a reliable safety system. Its construction from cast iron and steel, along with powder coating and packaging in a wooden box or as per request, ensures long-term durability under demanding workplace conditions.

FAQs of Grinding Pulverizer:

Q: How does the Grinding Pulverizer accommodate various materials and applications?

A: The pulverizer is engineered to handle a broad range of materials, including spices, minerals, chemicals, and grains. It features a feed size capability of up to 15 mm and adjustable grinding speeds, making it suitable for diverse industrial grinding and pulverizing needs.Q: What safety features are included in this surface grinding machine?

A: The machine is equipped with overload protection to prevent damage from excessive loads, and an air-cooled system to maintain proper operating temperature and enhance safety during continuous use.Q: When is maintenance required, and how easy is it to perform?

A: Routine maintenance is straightforward, thanks to its accessible design. Regular cleaning, blade inspection, and occasional lubrication help ensure optimal performance. The robust construction and powder-coated finish enhance durability and minimize maintenance frequency.Q: Where can this Grinding Pulverizer be installed and operated?

A: It is designed for industrial environments and must be floor-mounted for stable operation. With a compact floor space requirement (700 x 900 mm) and a weight of approximately 210 kg, it fits efficiently in most production facilities.Q: What is the benefit of a manual control system and non-computerized design in this model?

A: The manual control system offers simplicity and reliability, minimizing training requirements and reducing risks of electronic malfunction. Its non-computerized design ensures easy operation and maintenance, especially in demanding or remote industrial settings.Q: How does the air-cooled cooling system improve operational efficiency?

A: The air-cooled system prevents overheating during prolonged use, ensuring consistent machine performance and extending the longevity of components like the motor and blades.Q: What packaging options are available for shipment of the pulverizer?

A: Standard packaging is done in a secure wooden box to prevent damage during transit. Custom packaging options are available upon request to meet specific client requirements.

Price 200000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

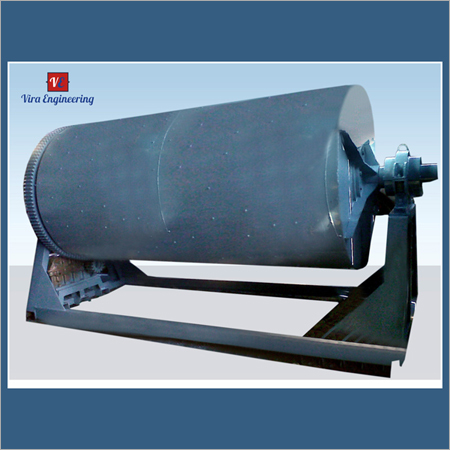

More Products in Grinding Equipment Category

Grinding Ball Mill

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Weight (kg) : 750 kg

Automatic : No

Grinding Length : 400 mm

Ball Mill

Price 1000000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Weight (kg) : 645 Tons depending on model

Automatic : No

Grinding Length : Up to 2250 mm

Batch Type Ball Mill

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel / Stainless Steel

Weight (kg) : Varies by model, 2000 kg and above

Automatic : Other, SemiAutomatic

Grinding Length : Customizable

Continuous Ball Mill

Price 2000000 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel/Alloy

Weight (kg) : 4000 kg to 40,000 kg

Automatic : Other, SemiAutomatic/Automatic

Grinding Length : Continuous operation

Send Inquiry

Send Inquiry Send SMS

Send SMS