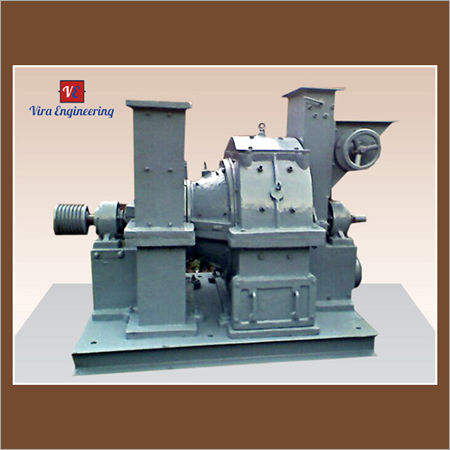

Grinding Ball Mill

Grinding Ball Mill Specification

- Rotation

- Horizontal

- Model

- GBM-200

- Product Type

- Grinding Ball Mill

- General Use

- Industrial Grinding and Milling

- Material

- Mild Steel

- Type

- Bench Type

- Capacity

- 40-200 kg/h

- Weight (kg)

- 750 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- No

- Control System

- Manual

- Table Size

- 200 x 400 mm

- Table Slide Way

- V and Flat

- Magnetic Chuck Size

- 200 x 400 mm

- Grinding Wheel Size

- 180 x 13 x 31.75 mm

- Grinding Wheel Speed

- 2850 RPM

- Grinding Length

- 400 mm

- Floor Space

- 1600 x 1200 mm

- Fuel Tank Capacity

- 35 L

- Spindle Speed

- 2850 RPM

- Power

- 2 HP

- Voltage

- 220 V

- Dimension (L*W*H)

- 1600 x 1200 x 1600 mm

- Feature

- High Efficiency, Low Maintenance

- Color

- Blue/Grey

- Discharge Size

- 0.0750.4 mm

- Motor Type

- Three Phase Induction Motor

- Shell Diameter

- 600 mm

- Drive Type

- Gear Drive

- Liner Material

- Rubber/Manganese Steel

- Max Feed Size

- 20 mm

- Minimum Order Quantity

- 1 Unit

- Application

- Cement, Ores, Minerals, Chemicals, Pigments

- Ball Loading

- 100-400 kg

- Noise Level

- 80 dB

- Mill Speed

- 32 RPM

- Coolant System

- Included

Grinding Ball Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Grinding Ball Mill

A Ball Mill Works On The Principle Of Impact And Attrition: Size Reduction Is Done By Impact As The Balls Drop From Near The Top Of The Shell. A Ball Mill Consists Of A Hollow Cylindrical Shell Rotating About Its Axis. . Two Tiers Fixed On Both End Of Mill, Which Are Rotate On Four Rollers. Rollers Are Fixed On Support And Oil Immersed. Mill Rotates On Four Roller And Two Tiers. Girth Gear Is Fixed On Shell, Which Driven Mating Gear, Gearbox And Motor, Which Are Fixed On Heavy Drive Base. It Is Partially Filled With Balls. Input Material Is Fed In Two Primary Grinding Compartments. Large Diameter Balls For Reduce Particle Size Are Lying Inside First Compartment. Material Comes Into Second Compartment For Further Grinding. Smaller Size Media Are Laying Inside This Compartment For Fine Grinding. Diaphragms May Place To Regulate Material Level And Control Retention Time. Material Is Feed And Discharged Through Hollow Trunnion At Opposite End. The Grinding Media Is The Balls, Which May Be Made Of Steel (Chrome Steel), Stainless Steel, Ceramic, Or Rubber. The Inner Surface Of The Cylindrical Shell Is Usually Lined With An Abrasion-Resistant Material Such As Manganese Steel Or Rubber. Less Wear Takes Place In Rubber Lined Mills.

Vira EngineeringS Ball Mill Is Widely Used In The Powder Production Lines, Such As Cement, Ceramics, Silicate, Refractory Materials, Chemical Fertilizer, Glass Ceramics, , Pencil, Paint , Marble, Coal, Minerals, Ferro Alloys Etc. According To The Need Of Customers And Material, Ball Mills Have Been Designed In Standard Sizes. Motor Hp And Production Is Totally Depends On Property Of Material And Require Fineness.

Efficient Industrial Grinding

The GBM-200 excels in grinding a variety of materials including cement, ores, minerals, chemicals, and pigments. Its horizontal rotation and precise speed control guarantee fine, uniform discharge and minimal loss of material. With integrated coolant and advanced liner options, the mill operates with reduced heat and wear, prolonging service life and maximizing efficiency for intensive industrial workflows.

Robust Construction and Manual Control

Constructed from premium-grade mild steel and reinforced with either rubber or manganese steel liners, the grinding ball mill is engineered for longevity and resilience. Its manual control system allows operators to adjust parameters directly, providing flexibility and precision over grinding processes. This makes it ideal for facilities requiring reliable equipment for demanding tasks without the complexity of CNC systems.

FAQs of Grinding Ball Mill:

Q: How is the GBM-200 Grinding Ball Mill operated and what control system does it use?

A: The GBM-200 is operated manually, featuring a straightforward control system without CNC or computerized components. Operators adjust the mills parameters using manual switches and levers, providing precise control over grinding speed, ball loading, and discharge rates.Q: What materials can be processed with this grinding ball mill?

A: This mill is suitable for grinding a wide range of materials including cement, ores, minerals, chemicals, and pigments. Its versatile design and robust build make it ideal for varied industrial applications.Q: When should I consider using a ball mill with rubber or manganese steel liners?

A: Choose rubber liners for applications requiring lower noise and reduced abrasion, mainly when processing soft or medium-hard materials. Manganese steel liners are recommended for heavy-duty milling tasks, especially when grinding hard or abrasive substances.Q: Where is this grinder primarily used, and what industries benefit most from its features?

A: The GBM-200 is primarily used in industrial sectors such as cement manufacturing, mineral processing, chemical production, and pigment milling. Its reliability and consistent output make it an essential choice for manufacturers and suppliers across India.Q: What is the process for loading grinding balls, and how does it affect overall performance?

A: Grinding balls are manually loaded into the shell, with an optimal range of 100-400 kg. Correct ball loading ensures efficient grinding, enhances output capacity (40200 kg/h), and reduces maintenance frequency due to balanced wear distribution.Q: How does the included coolant system benefit the milling process?

A: The built-in coolant system effectively dissipates heat generated during operation, maintaining temperature stability. This prevents overheating, reduces material degradation, and extends the life of both grinding wheel and liners.Q: What are the advantages of using a gear drive and three-phase induction motor in this bench-type ball mill?

A: The gear drive delivers reliable torque and steady rotation at 32 RPM, while the three-phase induction motor ensures powerful, energy-efficient operation at 2 HP and 220 V. Together, these features provide smooth, consistent milling with minimal noise (80 dB).

Price 1000000 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Equipment Category

Grinding Pulverizer

Price 200000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 1550 kg/h

Type : Surface Grinding Machine

Power : 2 HP

Grinding Length : 200 mm

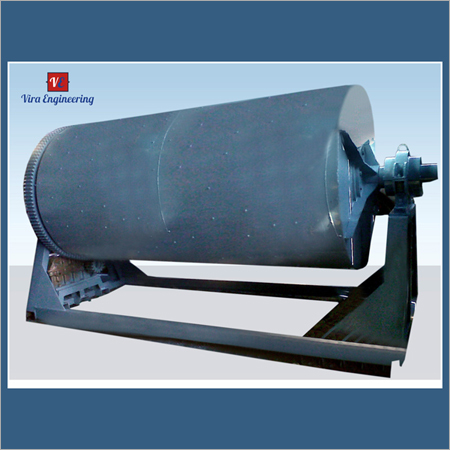

Ball Mill

Price 1000000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : Up to 100 TPH

Type : Other, Horizontal Cylindrical

Power : 7.5 75 kW

Grinding Length : Up to 2250 mm

Batch Type Ball Mill

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 100 kg to 5000 kg per batch

Type : Other, Batch Type

Power : Depends on batch size, typically 3 to 30 HP

Grinding Length : Customizable

Continuous Ball Mill

Price 2000000 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 500 kg/hr to 10,000 kg/hr or more

Type : Other, Continuous Ball Mill

Power : 10 KW 75 KW as per capacity

Grinding Length : Continuous operation

Send Inquiry

Send Inquiry Send SMS

Send SMS