Batch Type Ball Mill

Batch Type Ball Mill Specification

- Rotation

- Horizontal

- Model

- BTBM Series

- Product Type

- Batch Type Ball Mill

- General Use

- Grinding and mixing materials in batch processes

- Material

- Mild Steel / Stainless Steel

- Type

- Batch Type

- Capacity

- 100 kg to 5000 kg per batch

- Weight (kg)

- Varies by model, 2000 kg and above

- Computerized

- No

- Automatic

- Semi-Automatic

- CNC Or Not

- Not CNC

- Control System

- Manual Control

- Table Size

- Customizable

- Table Slide Way

- Heavy Duty

- Grinding Length

- Customizable

- Floor Space

- Depends on Capacity

- Spindle Speed

- Varies by Model

- Power

- Depends on batch size, typically 3 to 30 HP

- Voltage

- 220/440 V

- Dimension (L*W*H)

- Custom as per capacity requirement

- Feature

- High efficiency, robust construction, low maintenance

- Color

- Blue / Custom Color Available

- Safety Features

- Emergency Stop, Safety Guard Provided

- Maintenance

- Easy access for cleaning and maintenance

- Lining Material

- Rubber, Ceramic, or Manganese Steel

- Service

- Installation & Commissioning available

- Operating Mode

- Batch

- Drum Length

- 600 mm to 3200 mm

- Drum Diameter

- 600 mm to 3200 mm

- Ambient Temperature

- Upto 50C

- Application

- Paints, Ceramics, Chemicals, Minerals, Pharmaceuticals, Pigments

- Noise Level

- Low

- Discharge Type

- Over Flow/Grate Discharge

- Ball Material

- Steel/Alumina/Ceramic

- Drive Type

- Gear Motor / V-Belt

- Charging Size

- Up to 50 mm

Batch Type Ball Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Batch Type Ball Mill

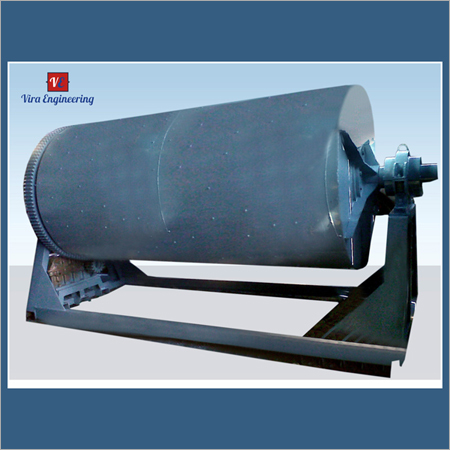

Batch Type Ball Mill

VIRA Engineerings Batch type ball mill is mainly used for mixing of the material, grinding, the fineness of the product is uniform, saving power. Batch Type Ball Mill useful for wet or dry powder grinding as well as homogenously mix more than two materials. Additives can be added for homogenously mixed during batch. It is for grinding Dyes, Ceramics, Pigment, minerals etc.

Batch Type Ball Mill Is Consist Heavy Duty Fabricated Shell With Both Side Bosses Provide For Providing Good Strength. Main Shaft Is Fixed On Both Side Bosses Of Shell. Main Shaft Is Supported On Both Sides Bearing & Housing. Entire Rotary Drum Assembly Is Mounted On Heavy-Duty Fabricated Structure. Inside Lining Can Be Done By Particular Material As Well As Design Based On Requirement. Material Charging Manhole Is Also Used For Mill Cleaning Purpose. Counter Balance Weight Is Fixed At Opposite Side Of Manhole, Which Help Mill To Rotate In Balance Condition.

Batch Type Ball Mill Is Working As Batch Type Operation. Adequate Size, Shape And Qty Grinding Media Is Placed Inside Rotary Drum From Inlet Port. Material Can Be Fed From Inlet Connection Provided In Shell. All Ports Need To Close Before Start Rotating Rotary Drum. Fed Material Rotates With Rotary Drum. Grinding Media Rotate And Dropped In Side And Reduce Particle Size. Mixing And Grinding Operation Being Done Simultaneously When Drum Rotates. Mill Is To Be Stop After Completion Of Batch And Remove Material From Outlet Port.

Advantages

- After Finished Material Is Discharged, Another Raw Material Can Be Put In For Grinding, CanT Continuous Feeding And Discharge Material.

- Different Liners And Grinding Media Can Be Used To Meet Different Requirements.

- The Fineness Of Grinding Material Depending On Milling Time

- It Can Be Used For Wet Or Dry Grinding, Finished Slurry Can Pass 1000Mesh Screen.

- Homogenously Mixed During Grinding

- Auto Feed Or Discharge By Screw Or Hopper.

Product details

| Automation Grade | Semi Automatic |

| Frequency [Hz] | 50 Hz |

| Material Grade | SS304 |

| Type Of Crushing Machines | Ball Grinding Mill |

| Voltage [V] | 440 V |

| Country of Origin | Made in India |

| Phase | 3 Phase |

| Power Source | Electricity |

| Material | Mild Steel |

| Brand | Vira Engineering |

| Capacity | 2 Ton |

| Usage/Application | Industrial |

Engineered for Versatility and Efficiency

Our Batch Type Ball Mill is specifically designed to handle diverse grinding and mixing needs in a broad spectrum of industries. With customizable dimensions, lining materials, and high-capacity options, it offers scalable solutions whether you are processing minerals, paints, or pharmaceuticals. Its semi-automatic operation, combined with heavy-duty construction, ensures efficient performance and lasting reliability.

Safety, Maintenance, and Support

We prioritize operational safety and user convenience. Every machine is equipped with an emergency stop and safety guard, while thoughtful design ensures easy access for cleaning and maintenance. Installation and commissioning services are available to support seamless setup, ensuring minimal downtime and maximum productivity from the outset.

FAQs of Batch Type Ball Mill:

Q: How does the Batch Type Ball Mill operate, and what materials can it process?

A: This ball mill functions in batch mode for grinding and mixing a range of materials such as paints, ceramics, minerals, chemicals, pharmaceuticals, and pigments. It uses steel, alumina, or ceramic balls inside a lined drum (rubber, ceramic, or manganese steel) to achieve uniform results in every batch.Q: What are the benefits of choosing rubber, ceramic, or manganese steel lining for the drum?

A: Each lining material serves specific needs: rubber provides excellent abrasion resistance and is suitable for softer materials; ceramic offers high purity and chemical resistance, ideal for sensitive compounds; manganese steel is robust and durable, best for mineral processing and hard materials.Q: Where can I install the Batch Type Ball Mill, and what are the power requirements?

A: The mill can be installed in any industrial facility that meets the required floor space based on the desired capacity. Power requirements depend on batch size, typically ranging from 3 to 30 HP, and voltage options include 220/440 V, making it suitable for most industrial settings in India.Q: What is the maintenance process, and how easy is it to clean the mill?

A: Maintenance is straightforward thanks to the mills accessible design. The drum and other key components can be reached easily for regular cleaning, lining inspections, and ball replacement, reducing downtime and ensuring optimal operation.Q: When should the ball mill be used in the production process?

A: Utilize the Batch Type Ball Mill during the grinding or mixing phase of your batch-oriented process. Its robust mechanism ensures consistent particle size reduction and even blending prior to subsequent manufacturing steps.Q: How does the over flow or grate discharge system affect product quality?

A: The discharge system (overflow or grate) influences material retention time and particle size control. Overflow discharge is ideal for finer products, while grate discharge enables higher throughput and controlled removal of processed material.Q: What safety features are included with the Batch Type Ball Mill?

A: The machine incorporates an emergency stop and a safety guard to ensure operator protection during use. These features meet standard industry safety practices, promoting safe handling and operation on the production floor.

Price 1000000 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Equipment Category

Grinding Ball Mill

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Product Type : Grinding Ball Mill

Color : Other, Blue/Grey

Power : 2 HP

Automatic : No

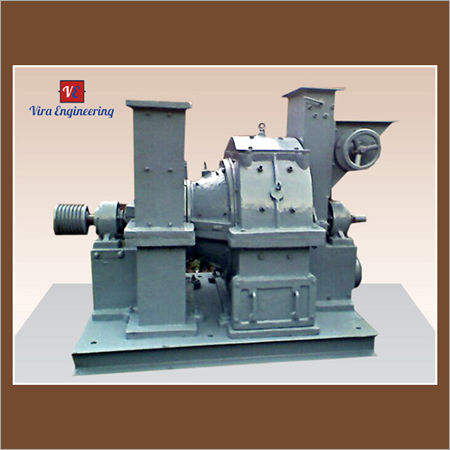

Grinding Pulverizer

Price 200000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Product Type : Grinding Pulverizer

Color : Other, Blue or as per requirement

Power : 2 HP

Automatic : Other, Semiautomatic

Ball Mill

Price 1000000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Product Type : Ball Mill

Color : Other, Blue / Customized

Power : 7.5 75 kW

Automatic : No

Continuous Ball Mill

Price 2000000 INR / Piece

Minimum Order Quantity : 1 Unit

Product Type : Ball Mill

Color : Other, Blue/Grey (customizable)

Power : 10 KW 75 KW as per capacity

Automatic : Other, SemiAutomatic/Automatic

Send Inquiry

Send Inquiry Send SMS

Send SMS