Continuous Ball Mill

Continuous Ball Mill Specification

- Model

- Continuous Ball Mill

- Rotation

- Horizontal

- Product Type

- Ball Mill

- General Use

- For continuous grinding and mixing of raw materials in cement, minerals, and ceramics industry.

- Material

- Mild Steel/Alloy

- Type

- Continuous Ball Mill

- Capacity

- 500 kg/hr to 10,000 kg/hr or more

- Weight (kg)

- 4000 kg to 40,000 kg

- Computerized

- No

- Automatic

- Semi-Automatic/Automatic

- CNC Or Not

- Not CNC

- Control System

- Manual/Automatic

- Grinding Length

- Continuous operation

- Floor Space

- Varies as per model; approximately 6m x 3m

- Spindle Speed

- Varies; typically 1838 rpm

- Power

- 10 KW 75 KW as per capacity

- Voltage

- 220 V / 380 V / 440 V

- Dimension (L*W*H)

- From 3000x1200x1200 mm onwards (size varies per model)

- Feature

- Continuous operation, robust construction, energy efficient

- Color

- Blue/Grey (customizable)

- Operation Mode

- Continuous

- WorkingSpeed

- 1838 rpm

- Installation

- Floor Mounted

- Drive Type

- Gear/Direct

- Feeding Size

- Upto 25 mm

- Discharge Size

- As fine as 100 mesh (150 micron)

- Ball Load

- 30% to 40% of mill volume

- Liner Type

- Rubber Lined or Manganese Steel

- Shell Thickness

- 10 mm to 40 mm

- Noise Level

- Low

- Application

- Used for cement, minerals, pigments, chemicals, ceramics

Continuous Ball Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Continuous Ball Mill

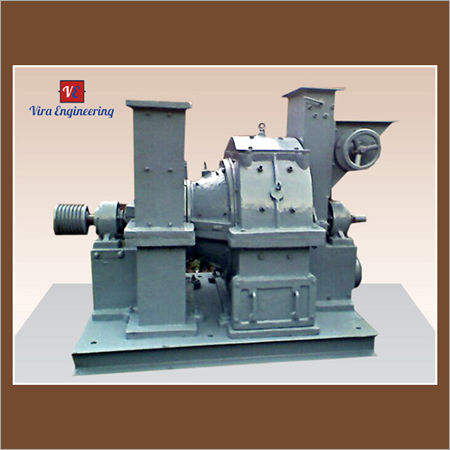

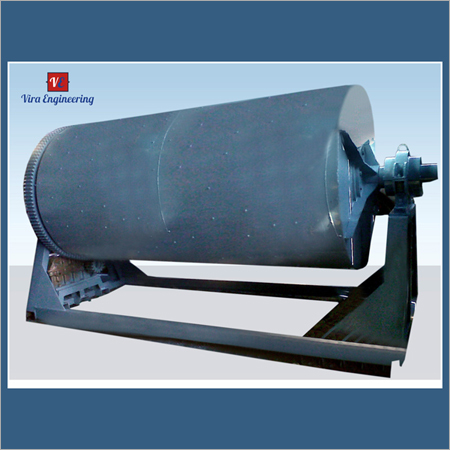

A Ball Mill Works On The Principle Of Impact And Attrition: Size Reduction Is Done By Impact As The Balls Drop From Near The Top Of The Shell. A Ball Mill Consists Of A Hollow Cylindrical Shell Rotating About Its Axis. . Two Tiers Fixed On Both End Of Mill, Which Are Rotate On Four Rollers. Rollers Are Fixed On Support And Oil Immersed. Mill Rotates On Four Roller And Two Tiers. Girth Gear Is Fixed On Shell, Which Driven Mating Gear, Gearbox And Motor, Which Are Fixed On Heavy Drive Base. It Is Partially Filled With Balls. Input Material Is Fed In Two Primary Grinding Compartments. Large Diameter Balls For Reduce Particle Size Are Lying Inside First Compartment. Material Comes Into Second Compartment For Further Grinding. Smaller Size Media Are Laying Inside This Compartment For Fine Grinding. Diaphragms May Place To Regulate Material Level And Control Retention Time. Material Is Feed And Discharged Through Hollow Trunnion At Opposite End. The Grinding Media Is The Balls, Which May Be Made Of Steel (Chrome Steel), Stainless Steel, Ceramic, Or Rubber. The Inner Surface Of The Cylindrical Shell Is Usually Lined With An Abrasion-Resistant Material Such As Manganese Steel Or Rubber. Less Wear Takes Place In Rubber Lined Mills.

Vira EngineeringS Ball Mill Is Widely Used In The Powder Production Lines, Such As Cement, Ceramics, Silicate, Refractory Materials, Chemical Fertilizer, Glass Ceramics, , Pencil, Paint , Marble, Coal, Minerals, Ferro Alloys Etc. According To The Need Of Customers And Material, Ball Mills Have Been Designed In Standard Sizes. Motor Hp And Production Is Totally Depends On Property Of Material And Require Fineness.

Product details

| Frequency [Hz] | 50Hz |

| Material Grade | SS304 |

| Shape | Round |

| Surface Finish | Color Coated |

| Voltage [V] | 440 V |

| Country of Origin | Made in India |

| Phase | 3 Phase |

| Power Source | Electricity |

| Material | Stainless Steel |

| Brand | Vira Engineering |

| Automation Grade | Automatic |

| Capacity | 500kg/hr |

| Usage/Application | Industrial |

| Power | 3Hp |

Versatile Grinding and Mixing Solutions

The continuous ball mill is ideally designed for the consistent grinding and blending of raw materials in industries like cement, minerals, and ceramics. Its adaptable liner optionsrubber or manganese steelensure optimal efficiency and durability in demanding applications. Floor mounting and various color customizations make it suitable for diverse plant layouts.

Efficient and Energy-Conscious Operation

Built for continuous use, the mill maintains a steady output with low noise and energy-efficient performance. Features such as manual or automatic control systems and power ratings from 10 KW to 75 KW (with voltage options of 220 V, 380 V, or 440 V) allow users to tailor operation according to specific production needs, maximizing throughput and minimizing downtime.

Robust Construction and Flexible Capacity

Manufactured from mild steel or alloy, the mill offers shell thicknesses between 10 to 40 mm and supports a ball load of 30%40% of volume, ensuring durability and consistent performance. Depending on the model, capacities can range from 500 kg/hr to over 10,000 kg/hr, with modular dimensions for easy integration into existing plant setups.

FAQs of Continuous Ball Mill:

Q: How does a continuous ball mill function in the grinding process?

A: A continuous ball mill grinds and mixes raw materials by rotating a horizontal shell filled with grinding balls. Raw materials are fed in from one end and move through the mill, getting finely ground and mixed, before exiting through the discharge as fine powder, suitable for use in cement, minerals, chemicals, or ceramics production.Q: What are the advantages of rubber-lined or manganese steel liners?

A: Rubber-lined mills offer reduced noise, lower wear, and minimized contamination, making them ideal for sensitive applications. Manganese steel liners provide enhanced durability and are suited for highly abrasive materials, ensuring the mill maintains efficiency over prolonged operational periods.Q: When is it recommended to use a continuous ball mill over a batch-type mill?

A: Continuous ball mills are preferred when large-scale, uninterrupted grinding and mixing are required, especially in industries such as cement, mineral processing, and ceramics, where consistent quality and high throughput are critical for production efficiency.Q: Where can continuous ball mills be installed and operated?

A: These mills are designed for floor-mounted installation in industrial environments, including manufacturing plants and processing units in India and abroad. The required floor space varies by model, typically around 6m x 3m, accommodating integration into various layouts.Q: What process controls are available with this continuous ball mill?

A: The mill is available with both manual and automatic control systems, allowing operators to adjust speed, power, ball load, and other parameters for optimized grinding performance. Users can select the level of automation best suited to their operational requirements.Q: How is the capacity of the continuous ball mill determined for specific applications?

A: Capacity depends on shell size, ball load, liner type, and selected operational speed. Models range from 500 kg/hr to over 10,000 kg/hr, enabling users to choose the right size according to plant demands and raw material properties.Q: What are the main benefits of using a continuous ball mill in industrial applications?

A: Key benefits include continuous operation for sustained productivity, robust and energy-efficient construction, customizable liner and control options, and fine discharge sizing suitable for a wide range of industrial applications, supporting reliable raw material processing and mixing.

Price 2000000 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Equipment Category

Grinding Ball Mill

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 40200 kg/h

Type : Other, Bench Type

Voltage : 220 V

Color : Other, Blue/Grey

Grinding Pulverizer

Price 200000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 1550 kg/h

Type : Surface Grinding Machine

Voltage : 220/440 V

Color : Other, Blue or as per requirement

Ball Mill

Price 1000000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : Up to 100 TPH

Type : Other, Horizontal Cylindrical

Voltage : 220440 V

Color : Other, Blue / Customized

Batch Type Ball Mill

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 100 kg to 5000 kg per batch

Type : Other, Batch Type

Voltage : 220/440 V

Color : Other, Blue / Custom Color Available

Send Inquiry

Send Inquiry Send SMS

Send SMS