Erection Commissioning and R&D Services

Erection Commissioning and R&D Services Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 15 Pieces Per Month

- Delivery Time

- 7-20 Days

About Erection Commissioning and R&D Services

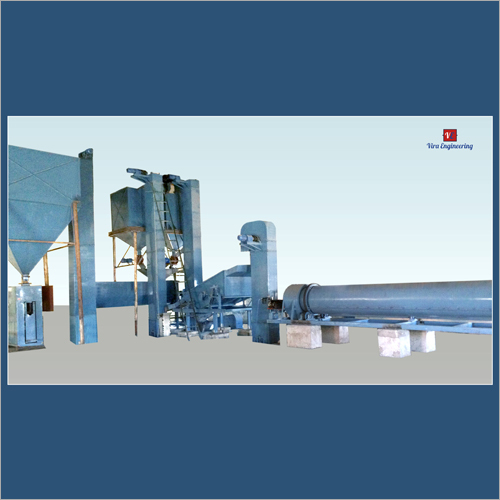

Manufacturing of equipments and delivery to site only completes 70% of the project as the real skills of an organization are put to test during erection and commissioning of the equipment. Erection & commissioning is a systematic and sequential process, the performance of which requires expertise in this field. Following this philosophy since our inception there have been several milestone achievements in this regard till date.

Continuous joint effort of experienced professionals, engineers, workers and statutory approvals has been a catalyst to meet targets resulting in customer satisfaction by successfully completing and handing over projects.

VIRA Engineering fully focuses on Customers plant to give qualities and successful insanitation and trial. So can plant comes actual production process and start the Production and financial cycle. VIRA Engineering always saves the clients financially investment, bank interest, time, and energy. We know for the easy and quality production system so investors get initial production, Quality and Marketing confidence. We are give e service of Trunkey plant and heavy Erection and commissioning.

Erection and commissioning" primarily refers to the installation and professional oversight of major industrial plant facilities and large equipment installation by qualified design engineering companies, etc. This type of Erection and Construction Commissioning activities may include oversight of construction of Oil Refineries, Rolling Mills, Reheating furnaces, Galvanizing lines, Annealing Furnaces, refractory, cement, mining, mineral processing unit, fabrication and erection of towers, piping, hydraulics, or the erection of giant steam, power generators, etc. There is no room for mistakes in that size of project. If someone specs the wrong size piping, or wrong steel, this delays the entire project, and may become million rupees mistakes.

Commissioning

It is necessary to dovetail the commissioning aspect of these projects right into the construction activities. The "Erection and Commissioning" agents must take responsibility for the correctness of the design documents, checklists, and the delivery of the plant equipment as well. So the entire "erection and commissioning" process is an integrated on-going process. After the erection of the plant and large equipment, then the equipment needs to be properly "commissioned" by well-experienced seasoned professionals. This is especially critical for large very expensive energy utilization equipment, such as natural gas turbines and compressors. These final commissioning activities include verifying construction phase tests, and commissioning testing.

The ultimate goal of the commissioning process to deliver to the owner, a project that is on schedule, has reduced first cost of delivery, and substantial life cost reductions, and meets the needs of the user and occupants, including a fully operational and optimized plant and system,

Research and Development

New Product Design And Development Is More Often Than Not A Crucial Factor In The Survival Of A Company. In An Industry That Is Changing Fast, Firms Must Continually Revise Their Design And Range Of Products. This Is Necessary Due To Continuous Technology Change And Development As Well As Other Competitors And The Changing Preference Of Customers. Without An R&D Program, A Firm Must Rely On Strategic Alliances, Acquisitions, And Networks To Tap Into The Innovations Of Others.

The Activities That Are Classified As R&D Differ From Company To Company, But There Are Two Primary Models, With An R&D Department Being Either Staffed By Engineers And Tasked With Directly Developing New Products, Or Staffed With Industrial Scientists And Tasked With Applied Research In Scientific Or Technological Fields Which May Facilitate Future Product Development. In Either Case, R&D Differs From The Vast Majority Of Corporate Activities In That It Is Not Often Intended To Yield Immediate Profit, And Generally Carries Greater Risk And An Uncertain Return On Investment.

Vira Engineering Knows For The Hard Working, Team Work, Well Behavior, Trust And Cooperative Nature. By Joint Venture We Are Research And Developing New Easy, Excellent, Low Maintenance, Low Processing Cost, Pollution Free, And Success Process, Products And Machines.

Vira Engineering Has All Advance Facility And Skill Team So We Are Developing At Our Own Setup But If Require Then We Are Also Give Services Like On Site Fabrication, Heavy Machinery/Plant Quality And Production Setup, Heavy Fabrication As Per Drawing, And Plant Maintenance Service .Mission Of Vira Engineering Is Always Give A Low Cost, Better Quality, Easy, On-Time And Clients Satisfaction Service, Our Other Services Are As Per Under;-

Services

- Erection

- Commissioning

- Research And Development

- Quality Development Of Existing Plant And Machinery

- On Site Fabrication And Development

- Heavy Machinery Work Setup And Fabrication Work As Per Drawings

Product List

- Crushing Equipment

- Grinding Equipment

- Drying Equipment

- Screening Equipment

- Mixing Equipment

- Conveying Equipment

- Pelletizing Equipment

- Kiln

- Separation Equipment

- Feeding Equipment

- Pollution Controlling Equipment

- Storage Equipment

- Brick Making Machine

- Erection-Commissioning And R&D Services

Robust Project Handling for Every Scale

Whether your project is small, medium, or large in scale, our team is structured to manage every requirement efficiently. We adapt our approach depending on project complexity, ensuring each phasefrom planning to completionis executed with precision and attention to detail. This flexibility enables us to serve diverse clients within industrial and manufacturing sectors across India.

Unwavering Safety and Quality Assurance

We strictly adhere to recognized industry safety standards, prioritizing a secure workplace for both personnel and equipment. Our quality assurance framework encompasses comprehensive testing and validation protocols, ensuring all deliverables align with regulatory and client-specific criteria while minimizing operational risks.

Comprehensive Support and Documentation

Our services include full technical documentation and project reports, vital for regulatory compliance and future reference. Customers benefit from our round-the-clock technical and onsite support, facilitating prompt troubleshooting and sustained project momentum, no matter where the site is located in India.

FAQs of Erection Commissioning and R&D Services:

Q: How is safety ensured during erection and commissioning projects?

A: Safety is a top priority in all our operations. We strictly follow industry-standard safety protocols at every project stage, conducting regular audits, using certified equipment, and providing employee training to mitigate risks and ensure a secure working environment.Q: What is the process for handling small, medium, and large-scale projects?

A: We tailor our project management approach based on scale and complexity. Each project begins with detailed planning, followed by strategic resource allocation, timely execution, and thorough validation. Our experienced professionals provide oversight to ensure milestones are met efficiently, regardless of project size.Q: When can I access technical or field support if an issue arises?

A: Our technical and onsite support services are available 24/7. Whether its during commissioning or after project handover, our support team addresses queries, troubleshooting, and emergencies at any time, minimizing downtime and ensuring smooth operations.Q: Where are your services available and what industries do you serve?

A: We provide pan-India onsite erection, commissioning, and R&D services, catering to industrial plants, process industries, manufacturing units, and engineering projects nationwide. Our team is strategically positioned to reach sites anywhere in India promptly.Q: What documentation is provided upon project completion?

A: Complete technical documentation and project reports are delivered for every project. These include testing results, validation records, process optimization data, and compliance records, supporting regulatory requirements and client quality standards.Q: How does your R&D expertise benefit my project?

A: Our R&D services focus on process optimization, innovation, and product development tailored to each client. Using state-of-the-art tools, our team identifies areas for efficiency, quality enhancements, and sustainable improvements, resulting in competitive advantages for your operations.Q: What are the primary advantages of choosing your commissioning services?

A: Clients benefit from experienced professionals, timely project execution, fully customized solutions, and a robust quality assurance framework. Continuous customer feedback integration further ensures that our services evolve with client needs, delivering lasting value.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 15 Pieces Per Month

- Delivery Time

- 7-20 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS