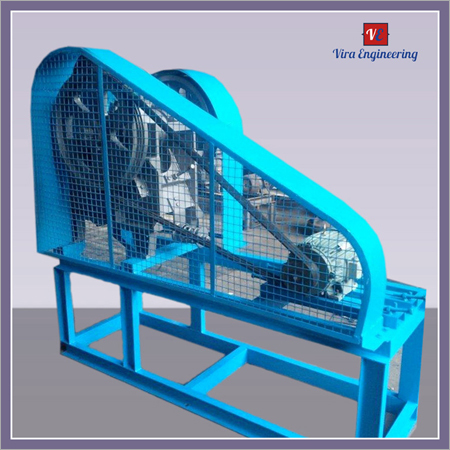

Roll Crusher

Roll Crusher Specification

- Model

- Available in different models

- Rotation

- Counter-rotating rollers

- Product Type

- Roll Crusher

- General Use

- Industrial crushing and material size reduction

- Material

- Mild Steel body, high manganese steel rollers

- Type

- Crushing Machine

- Capacity

- Up to 10 TPH or as specified

- Weight (kg)

- Up to 3500 kg (approx.)

- Computerized

- No

- Automatic

- No, Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual/Mechanical

- Grinding Length

- Depends on roller length

- Floor Space

- Approx. 2100 mm x 1400 mm

- Spindle Speed

- 350-400 rpm

- Power

- 7.5 HP 15 HP (varies by model)

- Voltage

- 220V/380V, 50/60 Hz

- Dimension (L*W*H)

- Approx. 2100 mm x 1400 mm x 1500 mm

- Feature

- Heavy duty, low noise, robust construction, easy maintenance

- Color

- Grey/Blue

- Feeding Size

- Up to 100 mm

- Discharge Size

- Adjustable, 0.5 mm to 40 mm

- Drive Type

- V-belt coupled with motor

- Number of Rollers

- 2 (Double Roll)

- Safety Features

- Overload protection, easy-to-access adjustment

- Roller Diameter

- 300 mm 600 mm

- Noise Level

- Low

- Surface Finish

- Painted / Powder coated

- Lubrication

- Centralized / manual

- Roller Material

- High manganese steel/alloy steel

- Installation Type

- Stationary

- WorkingSpeed

- As per model specifications

- Application

- Crushing coal, limestone, slag, minerals and ores

Roll Crusher Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Roll Crusher

A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particle, called the nip angle. The two rolls force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls. Some major advantages of roll crushers are they give a very fine product size distribution and they produce very little dust or fines. Rolls crushers are effectively used in minerals crushing. Usually, these crushers will have teeth or Smooth forms on the face of the roll. Roll crushers used for minerals and metal ores have smooth faced rolls.

Advantages

- High throughput capacity

- Cubicle product with minimal fines

- A variety of roll tooth profiles available

- Adjustable for change in product sizing

- Automatic tramp relief

- Minimal maintenance required

- Low cost per ton operation

Precision Crushing Performance

Engineered for uniform size reduction, the double roll crusher allows adjustable discharge settingsfrom 0.5 mm to 40 mmmaking it suitable for various industrial processes. Its counter-rotating rollers create even pressure, ensuring consistent particle size, while the feed size of up to 100 mm accommodates larger material chunks.

Durability and Safety

Manufactured with high manganese steel or alloy steel rollers, this crushing unit resists abrasion and deformation. Overload protection and easy-to-access adjustment features promote safe and hassle-free operation. The painted or powder-coated finish enhances both lifespan and visual appeal in demanding environments.

Efficient Operation and Maintenance

Driven by a V-belt coupled motor, the crusher operates at spindle speeds of 350400 rpm, with centralized or manual lubrication options for longer service life. Its low noise and heavy-duty design simplify installation and ongoing maintenance, making it ideal for continuous industrial use.

FAQs of Roll Crusher:

Q: How is the discharge size adjusted on the double roll crusher?

A: The discharge size can be easily set between 0.5 mm and 40 mm using the built-in adjustment mechanism, allowing operators to tailor the output to meet specific project requirements.Q: What are the main materials suitable for crushing with this roller crusher?

A: This machine is designed for industrial crushing of coal, limestone, slag, minerals, and various ores, making it versatile for multiple applications in material processing sectors.Q: When should routine lubrication and maintenance be performed?

A: Regular lubrication, either manual or centralized, is recommended according to usage frequency and working conditions. Maintenance checks should be scheduled to ensure optimal performance and longevity of components.Q: Where is this roll crusher typically installed?

A: Installation is stationary, ideally situated in industrial plants or facilities engaged in material reduction tasks, with a recommended floor space of approximately 2100 mm x 1400 mm.Q: What safety features are included in this roll crusher?

A: Safety is ensured by overload protection systems and easy-to-access adjustment points, reducing operator risk and enhancing overall machine reliability.Q: How does the V-belt coupled drive contribute to the crushers performance?

A: The V-belt coupled motor provides reliable power transmission, maintaining consistent spindle speed (350400 rpm) and reducing mechanical stress for smooth, efficient crushing.Q: What are the benefits of using high manganese steel rollers in this crusher?

A: High manganese steel rollers offer exceptional wear resistance, enhancing durability during heavy-duty industrial operations and leading to reduced maintenance costs over time.

Price 800000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crushing Equipment Category

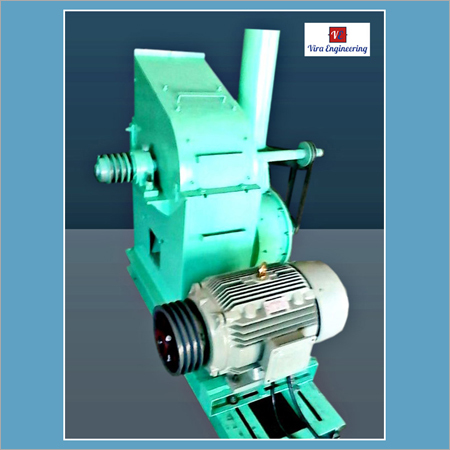

Jaw Crusher

Price 200000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel / High Manganese Steel

Automatic : No

Power : 5 20 HP (depending on model)

Control System : Manual

Hammer Mill

Price 200000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Automatic : Other, SemiAutomatic

Power : 5 HP

Control System : Manual

Send Inquiry

Send Inquiry Send SMS

Send SMS