Jaw Crusher

Jaw Crusher Specification

- Rotation

- Through Electric Motor

- Model

- Standard Jaw Crusher

- Product Type

- Jaw Crusher

- General Use

- Industrial Crushing, Mining, Construction Aggregates, Demolition Recycling

- Material

- Mild Steel / High Manganese Steel

- Type

- Crushing Equipment

- Capacity

- Up to 150 TPH (varies per model)

- Weight (kg)

- Approx. 1000-5000 kg depending on model

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Not CNC

- Control System

- Manual

- Floor Space

- Varies as per model (Approx. 1500 mm x 1000 mm)

- Spindle Speed

- 250-450 rpm

- Power

- 5 - 20 HP (depending on model)

- Voltage

- 220-440 V, Three Phase AC

- Dimension (L*W*H)

- Varies as per model; Approx. 1500 x 1000 x 1400 mm

- Feature

- High Crushing Ratio, Durable Structure, Easy Maintenance

- Color

- Yellow / Custom as per requirement

- WorkingSpeed

- Standard/Adjustable as per motor capacity

- Lubrication System

- Grease/Oil bath

- Application

- Stone, Granite, Coal, Iron Ore, Lime Stone, etc.

- Operating Noise Level

- Less than 80 dB

- Safety Switch

- Yes

- Crushing Method

- Compression

- Frame Construction

- Welded Steel

- Discharge Size

- 10-80 mm (Adjustable)

- Jaw Plate Material

- Manganese Steel

- Drive Type

- Belt Driven

- Feed Size

- Up to 300 mm

- Serviceability

- Easy Accessible Parts

Jaw Crusher Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Jaw Crusher

Jaw Crusher is mainly used as a primary crusher in a crushing circuit. The product is fed into the top of the crusher by vibrating grizzly feeder. The gap between the rolls is set according to the size of product, with the realization that the largest particle can only be 4 times the gap dimension. All the particles are drawn into the gap between the rolls with the help of rotating motion and a friction angle formed between the rolls called the nip angle. Usually, Jaw Crusher is effectively used in minerals crushing. It is used for minerals & metal ores have smooth faced rolls.

Mild steel fabricated crusher body is strengthened to withstand heavy load. Main (Eccentric) shaft is running on antifriction bearings. Jaw plates and chick plates are made from highly wear resistance manganese steel. Oscillating Jaw is fabricated from mild steel, which is fitted on main shaft. Both flywheels are work as pulleys. Flat OD wheel is for flat belt drive and V-grooved wheel is for V-belt drive. Out let gap can be varied easily by add OR remove mild steel plates between toggle plate and main body. VIRA Engineerings jaw crusher is generally used as a primary crusher in a crushing circuit. Product is fed into the top of the jaw crusher by feeder or hopper. The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jaw. Jaw crushers are run on belt drives driven by an electric motor. Jaw crushers are used extensively throughout the aggregate and mineral processing industry.

VIRA Engineerings offers bare jaw crusher units, modular and portable jaw crusher assemblies and entire crushing plants. Contact us for your jaw crushing needs.

Applications

- Primary Crushing

- Mining

- Aggregate

- Demolition

- Industrial

- Construction

- Environmental

- Bauxite, Hard Rock

- Lime stone, coal

- Iron ore, Manganese ore

Advantages

- Heavy Duty Jaw Crusher Design

- Long Life

- Cost Effective

- Standard Replacement Parts

- High Production

- Heavy Duty Forged Crank Shaft.

- Broad Range of Application

Product details

| Color | Blue |

| Power Source | Electricity |

| Surface Finish | Color Coated |

| Capacity | 50ton/hr |

| Brand | Vira Engineering |

| Automation Grade | Automatic |

| Country of Origin | Made in India |

| Voltage | 440 V |

| Phase | Single Phase |

| Material | Stainless Steel |

| Frequency | 60Hz |

| Power | 4Hp |

| Type Of Crushing Machines | Jaw Crusher |

| Usage/Application | Industrial |

Rugged Construction and High Crushing Efficiency

Built with welded steel frames and equipped with manganese steel jaw plates, the Standard Jaw Crusher ensures durability and reliable performance under heavy usage. Its compression-based crushing approach delivers a significant crushing ratio, suitable for diverse materials like stone, coal, granite, and iron ore. The adjustable discharge size, ranging from 10 to 80 mm, enables precise material output for varied industrial needs.

User-Friendly Features and Easy Maintenance

Designed with maintenance in mind, the crusher includes accessible lubrication points and easily replaceable parts. Its belt-driven mechanism and manual control system allow operators to adjust speeds and output according to motor capacity, ensuring optimal operation across different site requirements. The integrated safety switch and low operating noise enhance workplace safety and comfort.

Versatile Applications Across Industries

The Standard Jaw Crusher is ideal for use in mining operations, construction aggregate production, and demolition recycling. With a capacity of up to 150 TPH and compatibility with materials ranging from limestone to iron ore, this crusher supports both large-scale commercial projects and specialized material processing, making it a valuable asset for industrial suppliers and manufacturers in India.

FAQs of Jaw Crusher:

Q: How does the jaw crusher achieve high crushing ratios for various materials?

A: The jaw crusher utilizes a robust compression method and manganese steel jaw plates to efficiently break down hard substances like stone, granite, coal, and iron ore. The feed size of up to 300 mm and adjustable discharge size between 10 and 80 mm enable it to process large volumes with precise output, resulting in high crushing ratios.Q: What are the benefits of using a belt-driven jaw crusher in industrial applications?

A: A belt-driven system provides consistent torque and control over the crushers operating speed, which can be adjusted according to motor capacity. This enhances energy efficiency and allows operators to tailor the machines performance for different material types and processing requirements.Q: When should the lubrication system be checked during operation?

A: The jaw crusher is equipped with a grease or oil bath lubrication system. For optimum performance and longevity, it is recommended to inspect and service the lubrication points before each shift or operation cycle, especially when operating under heavy loads or extended hours.Q: Where can the Standard Jaw Crusher be installed?

A: This equipment is suitable for installation in industrial settings such as mining sites, construction aggregate facilities, and demolition recycling centers. Its compact footprint, with floor space approximately 1500 mm x 1000 mm, allows for flexible placement in various operational environments.Q: How does the safety switch protect operators during use?

A: The integrated safety switch ensures that the jaw crusher can be quickly deactivated in case of emergency or malfunction, preventing accidental startups and safeguarding operators from potential harm during maintenance or operation.Q: What process steps are involved in using the jaw crusher for material reduction?

A: Material is fed into the crusher up to 300 mm in size, where it is compressed between the manganese steel jaw plates. The adjustable discharge allows the processed material to exit in sizes ranging from 10 to 80 mm, suitable for further industrial applications or product requirements.Q: What are the major usage scenarios and benefits of this jaw crusher?

A: This jaw crusher excels in industrial crushing, mining, construction aggregates production, and demolition recycling. Its durability, high capacity (up to 150 TPH), and easy maintenance translate into cost-effective performance and reliability for suppliers and manufacturers across India.

Price 200000.00 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crushing Equipment Category

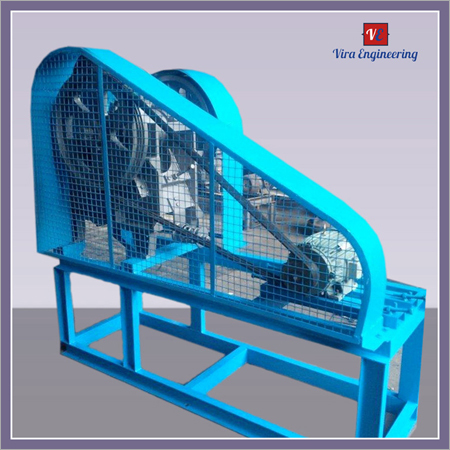

Roll Crusher

Price 800000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : Up to 10 TPH or as specified

Control System : Other, Manual/Mechanical

Power : 7.5 HP 15 HP (varies by model)

Spindle Speed : 350400 rpm

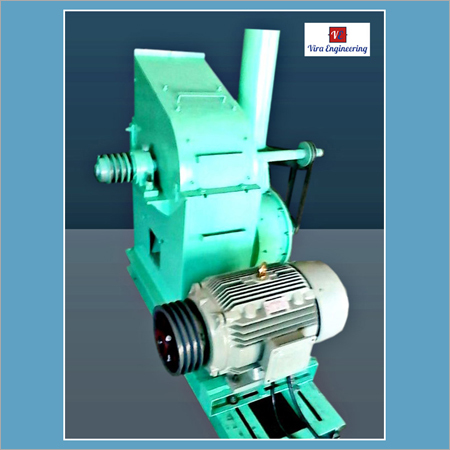

Hammer Mill

Price 200000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 200500 kg/hr

Control System : Manual

Power : 5 HP

Spindle Speed : 2800 RPM

Send Inquiry

Send Inquiry Send SMS

Send SMS