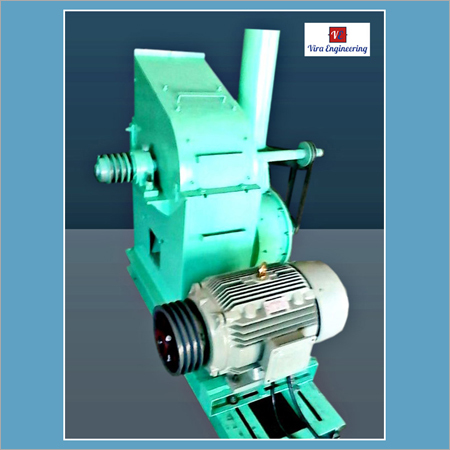

Hammer Mill

Hammer Mill Specification

- Rotation

- Clockwise

- Model

- HM200

- Product Type

- Hammer Mill

- General Use

- Grinding, crushing and pulverizing

- Material

- Mild Steel

- Type

- Semi-Automatic

- Capacity

- 200-500 kg/hr

- Weight (kg)

- 650

- Computerized

- No

- Automatic

- Semi-Automatic

- CNC Or Not

- Not CNC

- Control System

- Manual

- Floor Space

- Approx. 6 ft x 4 ft

- Fuel Tank Capacity

- Electric powered, no fuel tank

- Spindle Speed

- 2800 RPM

- Power

- 5 HP

- Voltage

- 440 V

- Dimension (L*W*H)

- 1800 mm x 1200 mm x 1500 mm

- Feature

- Robust construction, High output, Low maintenance

- Color

- Grey

Hammer Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units, Unit Per Month

- Delivery Time

- 7-20 Days

About Hammer Mill

The Basic Principle Is Straightforward. A Hammer Mill Is Essentially A Steel Drum Containing A Horizontal Rotating Shaft Or Drum On Which Hammers Are Mounted. The Hammers Are Free To Swing On The Ends Of The Cross, Or Fixed To The Central Rotor. The Rotor Is Spun At A High Speed Inside The Drum While Material Is Fed Into A Feed Hopper. The Material Is Impacted By The Hammer Bars And Is Thereby Shredded And Expelled Through Screens In The Drum Of A Selected Size.

Hammer Mill Comprises Of A Heavy Duty Mild Steel Fabricated Body (Alternatively Stainless Steel Construction Can Be Provided In Hammer Mill Wherever Necessary). The Grinding Chamber Of Hammer Mill Is Lined With Serrated Wear Plates, Which Protects The Body From Wear And Tear. A Dynamically Balanced Rotor In Hammer Mill With A Set Of Swing Hammers Accelerates The Grinding Process. The Screen Classifier Forms The Lower Half Of The Grinding Chamber Of Hammer Mill.

Advantages

- Easy To Change Screen In A Variety Of Sizes

- Reversible Hammers/Blades

- Cold And Silent Running

- Dust Free Working

- Long Life

- Minimal Maintenance Required

Product details

| Color | Green |

| Frequency | 60Hz |

| Material Grade | SS304 |

| Power Source | Electricity |

| Surface Finish | Color Coated |

| Voltage | 440V |

| Country of Origin | Made in India |

| Material | Mild Steel |

| Brand | Vira Engineering |

| Capacity | 10 Ton/Hour |

| Power | 50 HP |

Versatile Applications Across Industries

The HM200 Hammer Mill stands out for its adaptable design, making it suitable for a variety of industries such as agriculture, biomass, food processing, and mineral grinding. With its interchangeable screen and adjustable feed, the machine can easily be configured to meet the specific needs of different production environments.

Precision Engineering and Safety First

Constructed from durable mild steel and powder coated for longevity, the HM200 also emphasizes safety with features such as an emergency stop switch and a secure chamber lock. Its double row self-aligning ball bearings and air-cooled system ensure reliable operation during continuous use.

High Output, Low Maintenance Design

Delivering an output of 200500 kg/hr, the HM200 Hammer Mill combines high productivity with low maintenance requirements. Its belt drive mechanism minimizes mechanical wear, while the floor-mounted, compact design fits easily into standard workspaces, measuring 1800 mm x 1200 mm x 1500 mm.

FAQs of Hammer Mill:

Q: How does the HM200 Hammer Mill ensure operator safety during use?

A: The HM200 is equipped with key safety features like an emergency stop switch for immediate shutdown and a chamber lock that prevents the mill from operating when the chamber is open, significantly reducing operator risk.Q: What materials can be processed using this hammer mill?

A: This model is designed for a wide range of materials, including agricultural products, biomass, food items, and minerals, making it suitable for diverse applications in processing and grinding operations.Q: When is it necessary to change the interchangeable screen on the HM200?

A: You should change the interchangeable screen whenever you require a different discharge particle size or if the current screen shows signs of wear or clogging, ensuring optimal performance and desired output consistency.Q: Where can the HM200 Hammer Mill be installed in a manufacturing setup?

A: The machine is floor mounted, occupying a compact floor space of approximately 6 ft by 4 ft, and can be installed in most standard processing facilities, provided there is access to a 440 V electrical supply.Q: What is the process for adjusting the discharge particle size?

A: To adjust the discharge particle size, simply replace or modify the interchangeable screen within the hammer mill according to your required specifications, covering a range from 0.2 mm to 3 mm.Q: How does the built-in air cooling system benefit the milling process?

A: The air cooling system efficiently dissipates heat generated during prolonged operation, helping to maintain optimal machine temperature and ensuring consistent, reliable performance.Q: What are the advantages of using this semi-automatic hammer mill over fully manual alternatives?

A: With its semi-automatic functionality, robust build, and high output capacity, the HM200 offers efficient, consistent grinding and reduced labor requirements compared to fully manual models, while maintaining user control with a manual interface.

Price 200000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units, Unit Per Month

- Delivery Time

- 7-20 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crushing Equipment Category

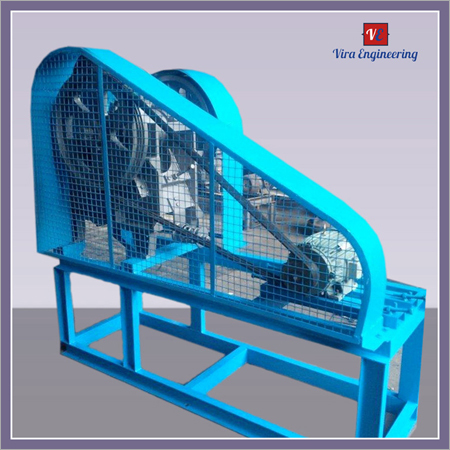

Roll Crusher

Price 800000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Spindle Speed : 350400 rpm

Type : Other, Crushing Machine

Dimension (L*W*H) : Approx. 2100 mm x 1400 mm x 1500 mm

CNC Or Not : Other, No

Jaw Crusher

Price 200000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Spindle Speed : 250450 rpm

Type : Other, Crushing Equipment

Dimension (L*W*H) : Varies as per model; Approx. 1500 x 1000 x 1400 mm

CNC Or Not : Other, Not CNC

Send Inquiry

Send Inquiry Send SMS

Send SMS