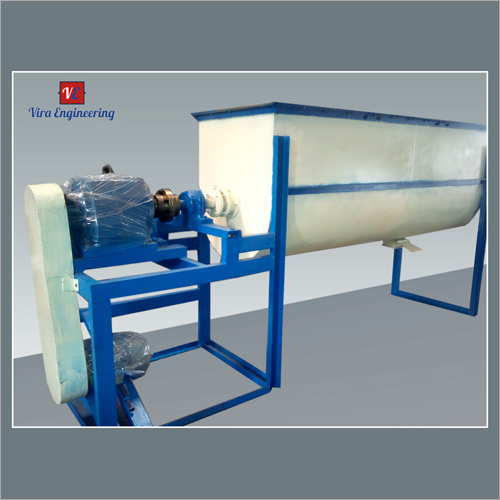

Ribbon Blender

Ribbon Blender Specification

- Surface

- Polished

- Motor Power

- 5 HP

- Product Type

- Ribbon Blender

- General Use

- Mixing Powder, Granules and paste in various industries

- Material

- Stainless Steel

- Type

- Horizontal Blender

- Capacity

- 200 - 1000 kg per batch

- Weight (kg)

- Approx. 800 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC or Panel Operated

- Method

- Batch Mixing

- Voltage

- 415 V

- Dimension (L*W*H)

- 2000 x 900 x 1200 mm

- Feature

- Uniform mixing, Easy cleaning, Robust design

- Color

- Silver

- Drive Mode

- Gearbox with Motor

- Mixing Time

- 15-30 minutes per batch

- Service Life

- Long Service Life

- Power Supply Phase

- Three Phase

- Blending Accuracy

- Up to 98%

- Maintenance

- Low Maintenance

- Safety Features

- Safety Guards & Emergency Stop Switch

- Working Volume

- 60-70% of total capacity

- Operating Temperature

- Ambient

- Design Type

- Customizable (as per client requirement)

- Discharge Type

- Bottom Discharge Valve

Ribbon Blender Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Ribbon Blender

The Vira EngineeringS Ribbon Blender Is Based On A Proven Agitator Construction That Provides A Triple Mixing Action Thus Ensuring Fast Efficient Blending. The Dimensions And Configuration Of The Ribbons In Ribbon Blender Are Carefully Balanced To Provide A Movement Of Material Within The Container That Avoids Dead Spots And Gives Rapid Product Discharge. The Design Of The ViraS Ribbon Blender Can Incorporate Features Required For A Customer'S Product Or Process Such As: Wear Resistance, Corrosive Resistance, Vacuum Filling And Discharge Arrangements, Special Shaft Seals, Heating/Cooling Jackets. Ribbon Blender Are Available In Sizes 100-6000 Liters In Stainless Steel And Mild Steel Construction. Bearing Mounted On Lanterns Outside Of Mixing Container To Avoid Contamination. Wide Range Of Arability. Feeding Through A Hopper Mounted On Top Of Blender.

Advantages

- This Machine Is Used For Mixing Powder Or Other Such Items In Order To Create A Perfect Blend Of Any Kind.

- The Drum Of The Mixer Rotates Both Reverse And Forward Direction.

- Material Inside The Drum Goes Up And Down As The Drum Moves.

- The Blades Inside The Drum Are Fitted In Such A Way That Any Type Of Powder Blends Into A Proper Form.

- Mixing Drum And Blades Are Made Out Of Good Quality Stainless Steel To Avoid Any Kind Of Chemical Reaction.

- Very Easy Cleaning Process.

- Sanitary Design-Heavy Gauge, Stainless Steel Constructions.

- Bearing Mounted On Lanterns Outside Of Mixing Container To Avoid Contamination

- Wide Range Of Arability.

- Feeding Through A Hopper Mounted On Top Of Blender.

Product details

| Material Grade | SS304 |

| Mixing Time | 6 Min |

| Power Source | Electricity |

| Surface Finish | Color Coated |

| Country of Origin | Made in India |

| Brand | Vira Engineering |

| Material | Stainless Steel |

| Color | White And Blue |

| Power | 5.5 kw |

| Frequency | 60Hz |

| Phase | 3 Phase |

| Voltage | 440V |

| Automation Grade | Automatic |

| Usage/Application | Industrial |

| Capacity | 3 Tons |

Efficient and Uniform Mixing

Experience thorough and consistent mixing of powders, granules, and pastes with the Ribbon Blenders horizontal design and advanced ribbon agitators. Whether working within pharmaceutical, food, or chemical sectors, youll achieve uniform results in every batch.

Safety First in Industrial Operations

Safety is integral to our Ribbon Blender. Equipped with safety guards and an emergency stop switch, the blender ensures secure operation while minimizing risks. Its robust construction also accommodates rigorous industrial use.

Customizable for Your Needs

This Ribbon Blender is crafted as per client specifications, making it adaptable to a variety of processes and production scales. The working volume ranges from 60-70% of total capacity, providing flexibility and efficiency for diverse applications.

FAQs of Ribbon Blender:

Q: How does the Ribbon Blender ensure uniform mixing in each batch?

A: The Ribbon Blender employs specially designed internal ribbons that rotate within the horizontal drum, effectively moving materials both radially and laterally. This mechanism, combined with a robust gearbox-driven motor, guarantees up to 98% blending accuracy within 1530 minutes per batch.Q: What safety features are included in the Ribbon Blender to protect users?

A: The blender is equipped with safety guards to prevent accidental contact with moving parts, and an emergency stop switch for immediate shutdown. These features prioritize operator safety during operation and maintenance.Q: When should the bottom discharge valve be used during the process?

A: The bottom discharge valve is utilized once mixing is complete. It allows fast and complete emptying of the blender, reducing product loss and ensuring efficient batch transfer for subsequent processing or packaging.Q: What industries or applications can benefit from using this Ribbon Blender?

A: This machine is suitable for mixing dry powders, granules, and pastes in industries such as pharmaceuticals, food, chemicals, and cosmetics. Its customizable design and robust construction make it versatile for a range of production environments.Q: How is the cleaning and maintenance process handled for this Ribbon Blender?

A: With its polished stainless steel surface and easy-access design, cleaning is straightforward and quick. The blender requires only minimal maintenance due to its durable construction and efficient operation, ensuring long service life.Q: What are the benefits of choosing a customized Ribbon Blender design?

A: Selecting a customized design ensures the blender matches your operational requirements in terms of capacity, control systems, and discharge methods, optimizing overall efficiency and productivity in your specific application.

Price 400000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mixing Equipments Category

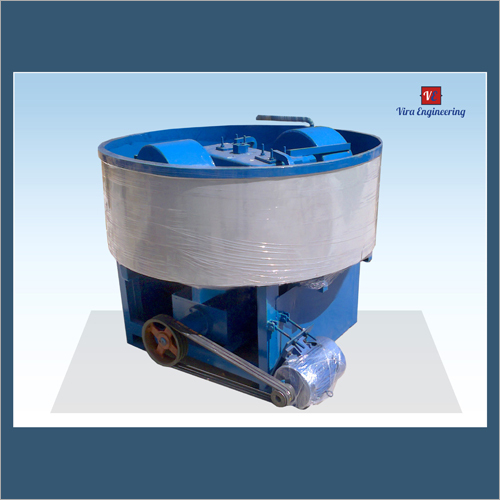

Counter Current Mixer

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Unit

General Use : Industrial mixing of concrete, mortar, and refractory materials

Automatic : Yes

Color : Other, Industrial Blue & Gray

Method : Other, Counter Current Mixing

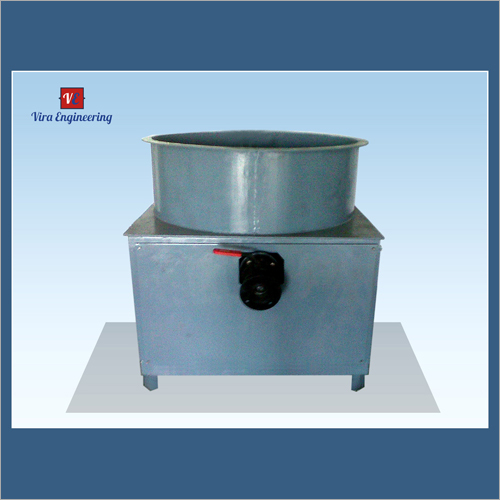

Muller Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

General Use : Mixing and grinding of powder, liquid and paste materials

Automatic : Other, SemiAutomatic

Color : Other, Blue / Grey

Method : Other, Mixing and Blending

Paddle Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

General Use : Mixing of powders, granules, chemicals, or food ingredients

Automatic : Other, SemiAutomatic

Color : Other, Metallic silver

Method : Other, Agitation and blending by paddles

Pan Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

General Use : Concrete Mixing

Automatic : Other, SemiAutomatic

Color : Green

Method : Other, Batch Mixing

Send Inquiry

Send Inquiry Send SMS

Send SMS