Counter Current Mixer

Counter Current Mixer Specification

- Surface

- Powder Coated

- Lifting Height

- 3 meters

- Lifting Speed

- 48 rpm

- Motor Power

- 55 kW

- Product Type

- Counter Current Mixer

- General Use

- Industrial mixing of concrete, mortar, and refractory materials

- Material

- Mild Steel

- Type

- Horizontal Mixer

- Capacity

- 1500 liters/batch

- Weight (kg)

- 3500 kg

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based Control Panel

- Cooling System

- Water Jacket Cooling

- Method

- Counter Current Mixing

- Voltage

- 415V (Three Phase)

- Dimension (L*W*H)

- 2450 x 1780 x 2460 mm

- Feature

- High Homogenization, Low Residue, Easy Discharge

- Color

- Industrial Blue & Gray

- Service Life

- >10 years

- Lubrication System

- Automatic Grease Lubricator

- Safety Features

- Overload Protection, Emergency Stop

- Noise Level

- 70 dB(A)

- Humidity Working Condition

- 90% RH

- Installation

- Floor Mounted

- Power Consumption

- Approx. 65 kW/h

- Discharge Type

- Hydraulic

- Blade Material

- High Tensile Steel

- Drive Type

- Gearbox & Electric Motor

- Maintenance

- Easy Access for Cleaning & Maintenance

- Mixing Efficiency

- 95%

- Batch Time

- 4-6 minutes

- Ambient Temperature Range

- 0 to 50C

Counter Current Mixer Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Counter Current Mixer

Kneading Rollers Are Mounted On Swiveling Drag Pins Attached To Mixing Star Housing Along With Mixing Scrapers. The Scrapers Are So Distributed As To Cover Every Sq.Inch Of Working Area With Minimum Tool Overhang Which Ensures Through & Homogeneous Mix. All The Moving Parts Of The Machine Are Provided With Anti-Friction Bearings With Sealing Arrangement. The Lubrication Points Are Easily Accessible. Special Care Has Been Taken To Make The Machine Leak-Proof From Dust. Motor Is Mounted On Rail Platform And Structure.

The High Energy Rotor Intensifies The Movement Of The Material Particles Resulting In Intensive Blending Of The Material. Moreover The Batch Is Rapidly & Completely Homogenized & De-Nodulised. The Mixing Star Comprising Of Four Mixing Blades Placed At Different Levels Force The Batch In The Vertical Movements As Well Because Of Their Specific Pitch. As Per Vira EngineeringS Special Design Fixed Oneself Rotate Agitator Which Is Self Rotate By Centrifugal Force And Work As A De- Nodulizer.

Vira EngineeringS Can Advent Many Inductees By High Quality & Sophisticated Mixer. Like Refractory, Magnesia Carbon, Alumina Manganese, Dolomite, Castables, Etc. The Need For Quick & More Homogeneous Mixing Was Strongly Felt. Vira Engineering Developed The High Efficiency Counter Current Mixer, Comprising Of A High Energy Rotor For Intensive Mixing. It Has Remarkable Advantages Over Conventional Mixer With Regards To More Homogeneous Mix, Reduced Mixing Time & Less Maintenance.

Advantages

- Quick ,Efficient & De-Nodulize Mixing

- Auto Mixing Cycle

- Smooth Operation.

- Heavy Duty Application

- Effective Sealing & Dust Proof Operation

- Quick & Complete Discharge

- Easy Maintenance

- High Reliability

Precision Mixing for Demanding Industries

Engineered especially for industrial applications, this Counter Current Mixer delivers superior homogenization with minimal residue. The horizontal design and advanced counter current mixing method guarantee even distribution of materials, making it ideal for producing high-quality concrete, mortar, and refractory blends. Its 1500-liter capacity supports large-scale operations without compromising consistency or efficiency.

Automatic Operation and Advanced Safety

Designed for reliability, this mixer is equipped with a PLC-based control panel, computerized settings, and automatic features. Safety is paramount, with integrated overload protection and an emergency stop button. The floor-mounted structure ensures stability, while the water jacket cooling system maintains optimal operating temperatures.

Built for Endurance and Easy Maintenance

The mixers high tensile steel blades and powder-coated mild steel frame ensure remarkable durability even under demanding usage. With service life spanning over a decade, minimal downtime is guaranteed. Maintenance is simplified thanks to easy-access design and an automatic grease lubrication system, ensuring smooth, long-term operation for industrial environments.

FAQs of Counter Current Mixer:

Q: How does the counter current mixing method improve efficiency in this mixer?

A: The counter current mixing method enhances efficiency by rotating the mixing blades and pan in opposite directions, ensuring that all ingredients are thoroughly incorporated. This process achieves a 95% mixing efficiency and superior homogenization, making it ideal for high-quality industrial materials.Q: What types of materials can be processed with this counter current mixer?

A: This mixer is suitable for the industrial production of concrete, mortar, and refractory materials. Its robust construction and advanced mixing mechanism handle varied consistencies and raw materials, providing excellent uniformity for each batch.Q: When should maintenance be performed on the mixer, and is it easy to access?

A: Routine maintenance should follow the manufacturers schedule, typically after a set number of batches or operational hours. The design features easy access points and an automatic grease lubricator for quick cleaning and lubrication, minimizing operational interruptions.Q: Where is the optimal installation location for this mixer?

A: The mixer is built for floor-mounted installation in industrial settings. It operates effectively in ambient temperatures from 0 to 50C and humidity conditions up to 90%, making it adaptable to diverse factory environments across India.Q: What safety features are included in the mixer?

A: For operator safety, it includes overload protection to prevent motor damage and an emergency stop function for immediate shutdown. Together, these features ensure a secure working environment during intensive industrial use.Q: How does the PLC-based control system benefit daily operation?

A: The PLC-based control panel offers user-friendly, computerized control for mixing parameters and batch management, reducing manual intervention and improving operational consistency and product quality.Q: What is the power consumption and motor capacity of this mixer?

A: The mixer operates with a 55 kW electric motor and consumes around 65 kW/h, ensuring robust performance with efficient energy use suitable for continuous industrial applications.

Price 500000.00 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mixing Equipments Category

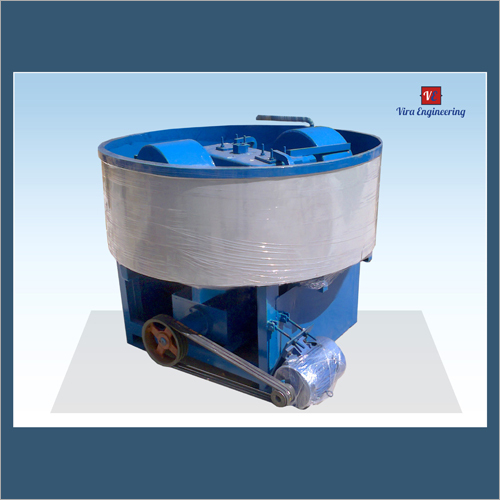

Muller Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 100 Kg to 2000 Kg per batch

Motor Power : 7.5 HP to 50 HP

Weight (kg) : 600 2500 kg

Automatic : Other, SemiAutomatic

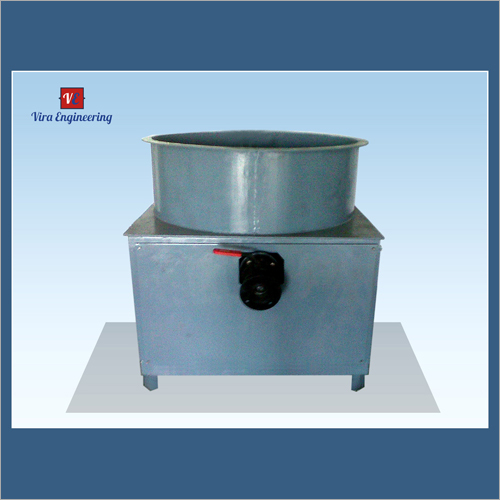

Pan Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 500 Liters

Motor Power : 5 HP Electric Motor

Weight (kg) : 950

Automatic : Other, SemiAutomatic

Paddle Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 500 Litres

Motor Power : 5 HP

Weight (kg) : 350 kg

Automatic : Other, SemiAutomatic

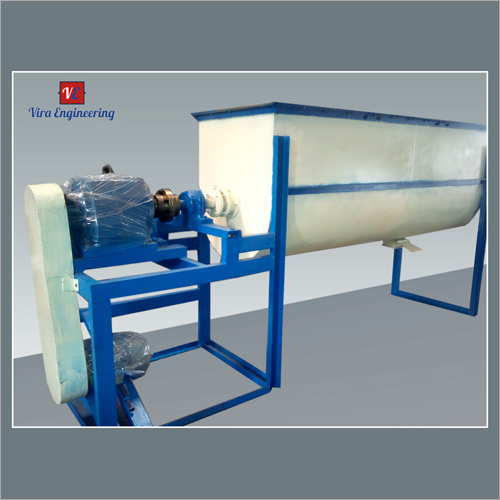

Ribbon Blender

Price 400000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 200 1000 kg per batch

Motor Power : 5 HP

Weight (kg) : Approx. 800 kg

Automatic : Yes

Send Inquiry

Send Inquiry Send SMS

Send SMS