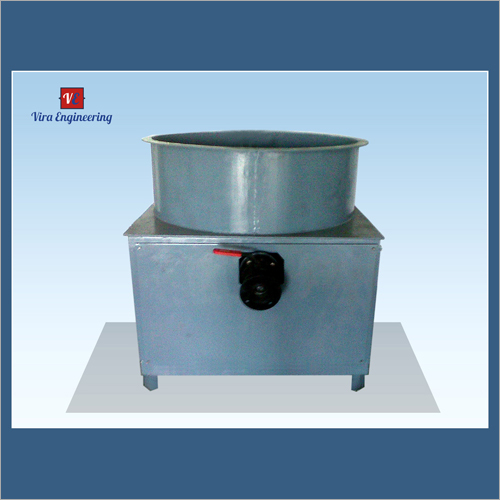

Pan Mixer

Pan Mixer Specification

- Motor Power

- 5 HP Electric Motor

- Surface

- Paint Coated

- Lifting Speed

- 20 RPM

- Product Type

- Pan Mixer

- General Use

- Concrete Mixing

- Material

- Mild Steel

- Type

- Batch Type

- Capacity

- 500 Liters

- Weight (kg)

- 950

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual/Starter Panel

- Cooling System

- Air Cooled

- Method

- Batch Mixing

- Voltage

- 415 V AC, 3 Phase

- Dimension (L*W*H)

- 1700 x 1450 x 1350 mm

- Feature

- Heavy Duty Construction

- Color

- Green

Pan Mixer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

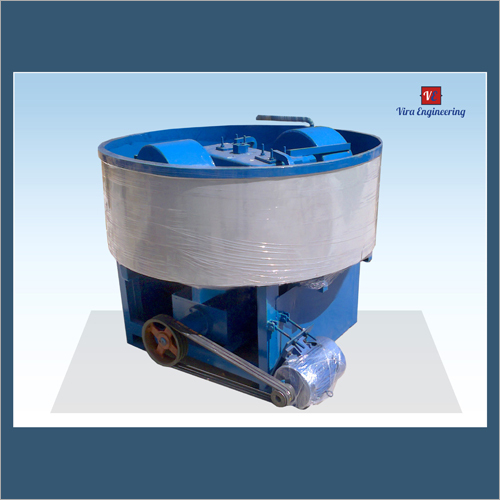

About Pan Mixer

As the name suggests, Pan mixer is a big pan like mixer which rotates the material in clockwise direction and discharge when it rotates in an anticlockwise direction. Paddle design & placement make sure superior mixing, while reducing dependence on gravity. One can also set the auto discharge system according to the requirements to collect the material and use for next process. Pan mixer also has the advantages of high automatic degree, high efficiency, less energy consumption, small noise, high discharging speed.

Pan Mixer Looks Like A Big Pan. You Will Recognize It Quickly And Easily From All Types Of Mixers. The Concrete Pan Mixer Machine Will Mix Material When It Rotates In A Clockwise Direction And Will Discharge Material When It Rotates In An Anticlockwise Direction. Paddle Design And Placement Assures Superior Mixing, While Eliminating Dependence On Gravity. We Can Also Set The Auto Discharge System To Collect The Material And Use For Next Process.

Vira Engineering Pan Mixer Have The Advantages Of High Automatic Degree, High Mixing Quality, High Efficiency, Low Energy Consumption, Small Noise, Easy Operation, High Discharging Speed, Convenient Maintenance, Etc. The Pan Mixer, A New Type Of Mixer, Is Applicable To Common Expressway, Power Station, Damming Construction, Road, Bridge, Big And Medium Prefabrication Factory, Agriculture. Chemicals, Ash, Ext.

Intensive Mixer

Intensive Mixture Has Same Working Principle Of Pan Mixture. But Here Pan Also Rotates In Opposite Direction Of The Scraper. It Is Giving More Effective Homogeneous Mixing Quality Within Minimum Duration.

Advantages

- High Mixing Quality, High Efficiency, Low Energy Consumption.

- Small Noise, Easy Operation, High Discharging Speed, Convenient Maintenance

- It Can Combine With Dosing Machine To Form A Small And Medium Batching Plant.

- The Machine Adopting Mobile Discharging Design,

- Both The Arms And Blades Detachable For Easy Maintenance.

- Spring Action To Absorb Shocks For Arms Type Mixer.

Product details

| Material Grade | SS304 |

| Power Source | Electricity |

| Country of Origin | Made in India |

| Power | 4Hp |

| Color | Grey |

| Material | Mild Steel |

| Output Capacity | 560 Liters |

| Brand | Vira Engineering |

| Automation Grade | Automatic |

| Mixer Type | Pan Mixer |

| Frequency | 50Hz |

| Surface Finishing | Color Coated |

| Phase | Single Phase |

| Voltage | 380V |

| Type Of The Drum Mixer | Tilting Drum Mixer |

| Usage/Application | Industrial |

Efficient and Reliable Mixing Performance

Designed for batch-type operations, this pan mixer delivers consistent and homogeneous mixes of concrete, fly ash, and refractory materials using three robust alloy steel mixing arms. Its gearbox-driven mechanism ensures powerful and even mixing, while the 10 mm drum thickness stands up to rigorous use in demanding construction environments.

User-Friendly Features and Operation

Top-fed loading, a manual or auto bottom discharge, and a manual centralized greasing system ensure smooth operation and easy maintenance. Convenient access panels allow for straightforward routine servicing, while the emergency stop button provides essential operator safety. An integrated water meter provision aids in precise water measurement.

Versatile Applications Across Industries

With a 500-liter capacity and batch mixing method, this versatile pan mixer is suitable for concrete production, fly ash blending, and refractory material preparation. The heavy-duty, paint-coated body and 415V, 3-phase motor support reliable long-term use, making it a preferred choice for manufacturers and suppliers across India.

FAQs of Pan Mixer:

Q: How is material loaded and discharged in the pan mixer?

A: Material is fed from the top through the input feeding system, and discharge is performed via a bottom door, which can be operated either manually or automatically depending on the model. This system ensures quick and efficient emptying of the mixed batch.Q: What safety features are incorporated into this mixer?

A: For user safety, the pan mixer includes a prominently placed emergency stop button that can quickly halt all operations in case of emergency. Easy open maintenance panels also facilitate safe and convenient access for routine checks and servicing.Q: When is this pan mixer most beneficial to use?

A: This mixer is highly beneficial for medium- to large-scale concrete or refractory material mixing operations, where consistent batch quality and durability are critical. Its robust construction and efficient mixing make it ideal for industrial, construction, and manufacturing environments.Q: Where can this pan mixer be effectively utilized?

A: It is well-suited for use in concrete product manufacturing plants, construction sites, and industries dealing with fly ash or refractory materials, particularly where high output and batch consistency are essential.Q: What is the process for mixing materials in this equipment?

A: Operators load raw materials through the top, set water quantities using the built-in meter, and activate the mixer. Alloy steel mixing arms rotate to blend contents uniformly, and once mixing is complete, the batch is discharged from the bottom door for further processing or transfer.Q: How does the maintenance access feature benefit users?

A: Easy open panels provide quick access to internal components, enabling hassle-free routine maintenance and inspections. The manual centralized greasing system further simplifies lubrication tasks, prolonging equipment life and reducing downtime.

Price 300000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mixing Equipments Category

Counter Current Mixer

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Weight (kg) : 3500 kg

Voltage : 415V (Three Phase)

Control System : Other, PLC Based Control Panel

Material : Other, Mild Steel

Muller Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Weight (kg) : 600 2500 kg

Voltage : 415 V

Control System : Other, Manual / PLC Based

Material : Other, Mild Steel / Stainless Steel

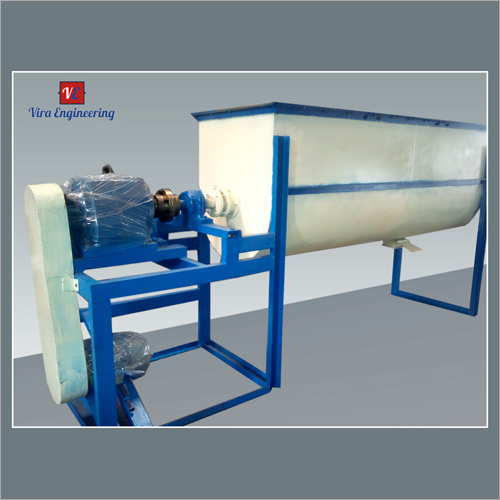

Paddle Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Weight (kg) : 350 kg

Voltage : 415 V, 50 Hz

Control System : Other, Manual/Panel operated

Material : Other, Stainless Steel

Ribbon Blender

Price 400000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 800 kg

Voltage : 415 V

Control System : Other, PLC or Panel Operated

Material : Other, Stainless Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS