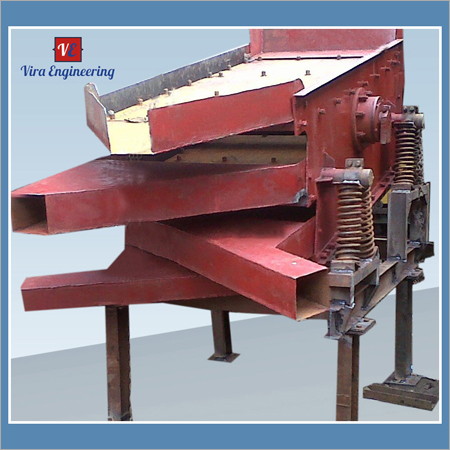

Vibrating Screen

Vibrating Screen Specification

- Type

- Vibrating Screen

- Material

- Mild Steel / Stainless Steel

- Processing Type

- Fabrication

- Condition

- New

- Shape

- Round

- Capacity

- 500 kg/hr to 2 T/hr

- Diameter

- 600 mm to 1800 mm

- Layer

- Single / Multi layer

- Dimension (L*W*H)

- As per model

- Power Mode

- Electric

- Voltage

- 220-240 V

- Power Consumption

- 1.5-3 kW

- Media

- Screen Mesh

- Noise Level

- Low

- Frequency

- 50-60 Hz

- Application

- Industrial Screening, Separation, Grading

- Coating Type

- Powder Coated

- Speed

- 1440 RPM

- Weight

- 150 kg to 750 kg

- Driven Type

- Motorized

- Motor Type

- Vibration Motor

- Discharge Size

- Up to 100 mesh

- Installation Method

- Floor Mounted

- Color

- Industrial Grey / Custom

- Surface Finish

- Smooth

- Portability

- Non-portable

- Feeding Size

- Up to 10 mm

- Usage

- Screening of Powder, Granules, Minerals, Chemicals

- Screen Mesh Size

- Customized (as per requirement)

- Automation Grade

- Semi-Automatic / Automatic

Vibrating Screen Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 7-20 Days

About Vibrating Screen

The Vibrating Screen is widely used as a standard particle where large capacity and high efficiency screening is desired. It is widely used in mining, coal, building material, Cement, refractory metallurgy, chemical, and various other metals and minerals industry. The vibrating screen is comprises of screening box, springs, absorber system, Vibrating motor and the base plate and structure. Simple Construction, Easy to Operate, Accurate Separation are some features of our Vibrating Screen.

Industrial Vibrating Screen Are Used As Standard Practice Where Large Capacity And High Efficiency Of Screening Are Desired. Vibrating Screen Mainly Used In Metallurgy, Mining, Coal, Building Material, Chemical, Cement, Refractory And Other All Metals And Minerals Industry.

The Vibrating Screen Composed By The Screening Box, Vibrating Motor, Springs, Absorber System And The Base Plate And Structure. Screening Box Completely Fix With Screen , Screening Frame, Liner, Shafting Ext, By The Vibration Motor Or Weight Balance Create The Excitation Force And Its Pass To Incline Screen Box Through Springs Then Material Will Enter Screen Box From Feeding Port , Material Moving Quickly And Separately Loose Through Sieve Completing Screening Work.

Vira Engineering Manufactured Vibrating Screen In A Wide Range Of Sizes For Varying Application And Production Demands. Vibrating Screen Design Finalize On The Type Of Material And Application. Basically There Are Three Type Of Driven Screen.

Other Future

- Vibro Motor Drive Type Vibrating Screen.

- Weight Balance Vibration Type Vibrating Screen.

- Eccentric Drive Type Vibrating Screen.

Advantages

- Simple Construction

- Maintenance Free

- Versatile

- Accurate Separation

- Easy To Operate

- Increased Capacity Per Square Foot

Product details

| Material Grade | SS304 |

| Power Source | Electricity |

| Surface Finish | Color Coated |

| Country of Origin | Made in India |

| Type Of Machine | Linear |

| Material | Stainless Steel |

| Color | Brown |

| Voltage | 440V |

| Motor Power | 3 HP |

| Frequency | 60Hz |

| Capacity | 300kg |

| Brand | Vira Engineering |

| Usage/Application | Industrial |

| Automation Grade | Automatic |

Custom Mesh for Precise Results

Our vibrating screens offer fully customizable mesh sizes, ensuring accurate separation and grading regardless of the material type. Whether you process fine powders or granular minerals, mesh customization allows you to achieve optimal efficiency and product consistency.

Robust Design Meets Versatility

Constructed using mild or stainless steel and powder coated for durability, these screens are built to perform reliably even in tough industrial conditions. The floor-mounted, non-portable design ensures operational stability while the smooth surface finish prevents material build-up.

Efficient Operation, Low Power Consumption

Fitted with energy-efficient vibration motors, our screens deliver continuous performance with low electricity use (1.53 kW) and minimal noise. The semi- or fully automatic options, combined with electric power and straightforward installation, enhance productivity.

FAQs of Vibrating Screen:

Q: How does the customized mesh size benefit the screening process?

A: Customizing the screen mesh size allows you to tailor the separation to specific particle requirements, ensuring optimal product quality and process efficiency for various materials such as powders, granules, minerals, and chemicals.Q: What is the typical installation process for this vibrating screen?

A: The vibrating screen is designed for floor mounting and comes with the necessary fittings. Installation involves securely placing the unit on a flat surface, connecting the vibration motor to the power supply (220240 V), and configuring operating settings as required.Q: When should I choose a multi-layer versus a single-layer screen?

A: Multi-layer screens are ideal when you need to separate materials into multiple grades or particle sizes in a single pass, whereas a single-layer screen is sufficient for basic grading or separation tasks.Q: Where can this vibrating screen be utilized?

A: This equipment is well-suited for a range of industrial settings, including powder processing, chemical plants, mineral handling facilities, and granule grading operations throughout India.Q: What are the advantages of using an electric vibration motor at 1440 RPM?

A: An electric vibration motor running at 1440 RPM ensures consistent and effective screening by generating the necessary vibratory motion. It provides uniform material distribution and reliable throughput suited to both semi-automatic and automatic workflows.Q: Is the vibrating screen suitable for separating fine particles?

A: Yes, with discharge sizes up to 100 mesh and fine mesh customization, the screen is perfectly suitable for precise separation of fine powders and small granules.

Price 250000.00 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 7-20 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screening Equipment Category

Gyro Screen

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Mode : Electric

Frequency : 5060 Hz

Layer : Single or MultiLayer

Power Consumption : 13 kW

Send Inquiry

Send Inquiry Send SMS

Send SMS