Gyro Screen

Gyro Screen Specification

- Type

- Vibratory Separator

- Material

- Stainless Steel

- Processing Type

- Automatic

- Condition

- New

- Shape

- Round

- Capacity

- 100 kg/hr to 2,000 kg/hr

- Diameter

- 24 to 72

- Layer

- Single or Multi-Layer

- Dimension (L*W*H)

- Customized

- Power Mode

- Electric

- Voltage

- 220-240 V

- Power Consumption

- 1-3 kW

- Media

- Dry & Wet

- Noise Level

- Low

- Frequency

- 50-60 Hz

- Application

- Screening, Separation, Grading, Filtering, Sifting of Granules & Powder

- Coating Type

- Powder Coated

- Usage Industry

- Pharmaceutical, Food Processing, Chemical, Minerals, Plastic

- Finish Type

- Mirror/Matte

- Mobility

- Movable with Caster Wheels

- Automation Grade

- Semi-Automatic and Fully Automatic

- Installation

- Easy Setup

- Safety Features

- Overload Protection

- Temperature Resistance

- Up to 120C

- Screen Mesh Size

- 10 to 500 mesh

- Drive Type

- Vibration Motor

- Feed Capacity

- Adjustable

- Cleaning

- Quick Release System

- Discharge Outlet

- Side & Bottom Discharge

Gyro Screen Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Gyro Screen

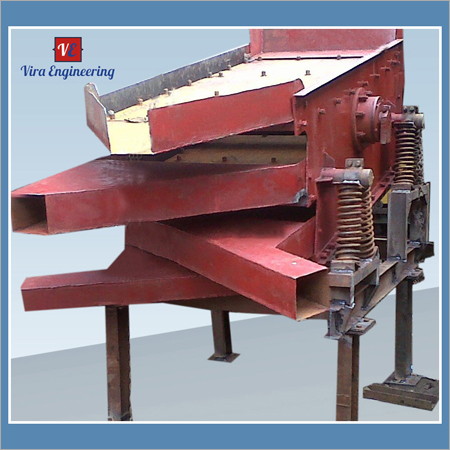

Gyro Screen also known as "Shifter" is a highly efficient screen with adjustable multi-plane component mechanical vibration. A spring-mounted screen for grading, separating and sifting powders. It is used widely in almost all processing industries like chemicals, plastics, pharmaceutical and food. Moreover, it has the ability to separate materials up to five fractions. The heart of Gyro Screen is Vibrator Motor which is designed for smooth continuous operation. It is a best screening equipment for getting perfect screening separation ratio doesnt get recycling material.

The Gyro Screen is called as Shifter also. VIRA Engineering is leading manufacturer of Gyro Screen and got successes in various industries. The Gyro screen is a circular highly efficient Gyratory screen with adjustable multi-plane component mechanical vibration. The heart of gyro screen is the robust specially made vibrator motor which is designed for long trouble free continuous operation. . New technology shifter is giving horizontal, vertical and circular mechanical vibration the vibrator motor has double extended shaft fitted at each end with variable eccentric weight. Motor is rigidly mounted on circular vibrating table on rugged springs. Number of interchangeable spacing frames having discharge outlets along with tensions rings fitted with screens cloth can be mounted one on top of the other, on the Vibrating table with the help of clamp rings. Gyro screen provides optimum screening & assures maximum feed-rate & efficiency. It best screening equipment for getting accurate screening separation ratio doesnt get recycling material.

It Useful For Screening Starch, Pharmaceuticals, Animal Feeds, Food Product, Agro Product, Agro Chemicals, Fertilizers, Gum Powder, Metal Powder, Chemicals, Minerals, Agrochemicals, Dyes, Pigment, Ceramics, Minerals, Paints, Polymers, Magnetic Material, Papers Etc Product.

Advantages

- Low Power Consumption

- Varied Range Of Application

- High Processing Rate Per Unit Area Of Screen

- Accurate Separation

- Minimum Screen Building

Product List

- Crushing Equipment

- Grinding Equipment

- Drying Equipment

- Screening Equipment

- Mixing Equipment

- Conveying Equipment

- Pelletizing Equipment

- Kiln

- Separation Equipment

- Feeding Equipment

- Pollution Controlling Equipment

- Storage Equipment

- Brick Making Machine

- Erection-Commissioning And R&D Services Gallery

Efficient and Versatile Separation

Designed for reliability across multiple industries, the Gyro Screen efficiently separates, grades, and filters various materials. With mesh sizes from 10 to 500 and support for both dry and wet media, it ensures precise results for pharmaceutical, food processing, chemical, mineral, and plastic sectors. The mirror or matte finish provides durability and easy cleaning, supporting strict hygiene requirements.

User-Friendly Setup and Operation

This vibratory separator features easy installation with a quick-release cleaning system, making maintenance convenient and downtime minimal. Adjustable feed capacity and caster wheels grant operational flexibility, while automation options (semi and fully automatic) allow users to choose control levels to match their process needs.

Performance and Safety Assured

With robust temperature resistance up to 120C and overload protection, the Gyro Screen safeguards both users and materials during operation. Its low noise output creates a comfortable working environment, and the powder-coated, stainless steel construction ensures longevity and high performance even under challenging conditions.

FAQs of Gyro Screen:

Q: How does the Gyro Screen ensure efficient screening and separation?

A: The Gyro Screen utilizes a vibration motor drive and customizable mesh sizes (10 to 500 mesh) to provide precise and consistent separation, grading, and sifting of both dry and wet granules or powders. Its adjustable feed capacity and multi-layer option enhance efficiency across various processing needs.Q: What benefits do the mirror and matte finishes offer for this vibratory separator?

A: The mirror and matte finishes enhance the Gyro Screens durability and resistance to corrosion while simplifying cleaning and maintenance, making it suitable for industries with stringent hygiene requirements such as food processing and pharmaceuticals.Q: Where can this Gyro Screen be used, and what industries benefit from it most?

A: This equipment is ideal for industries including pharmaceuticals, food processing, chemicals, minerals, and plastics. It efficiently supports processes like screening, filtering, and grading in settings where precise particle separation and hygiene are critical.Q: What is the process for setting up, operating, and cleaning the Gyro Screen?

A: Installation is straightforward, thanks to its easy setup design and mobility with caster wheels. Operation is flexible, with options for semi-automatic or fully automatic control. Cleaning is simplified by a quick-release system, allowing for fast changeovers and minimal downtime.Q: How does the Gyro Screen handle safety and operational reliability?

A: Equipped with overload protection and designed to withstand temperatures up to 120C, the Gyro Screen ensures a safe working environment. Its electric, low-power consumption motor operates quietly to minimize workplace disruptions.Q: When should a user opt for a multi-layer Gyro Screen configuration?

A: Multi-layer configurations are recommended when processing materials that require simultaneous separation into multiple size fractions, increasing throughput and operational flexibility for high-volume or multi-product applications.

Price 200000.00 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screening Equipment Category

Vibrating Screen

Price 250000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Media : Screen Mesh

Shape : Other, Round

Frequency : 5060 Hz

Condition : New

Send Inquiry

Send Inquiry Send SMS

Send SMS