Paddle Dryer

Paddle Dryer Specification

- Material

- Stainless Steel

Paddle Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID)

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Paddle Dryer

Paddle Dryer

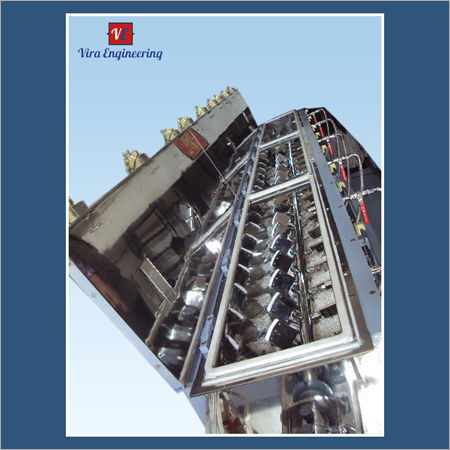

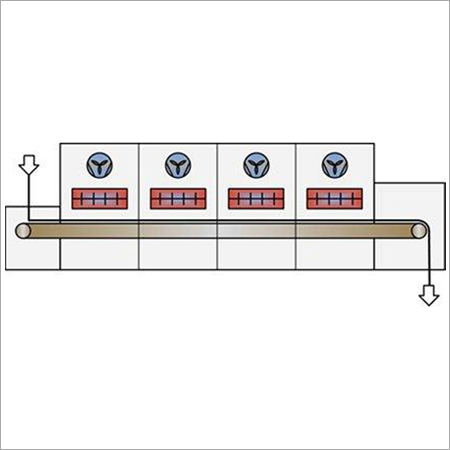

Paddle dryer is a low speed agitating type of equipment with special fan-shaped paddles which provide continuous indirect heating. It is suitable for drying/cooling pastes, cakes, powders, and granules materials. This machine greatly improves the heat transfer efficiency through local stirring, mixing and self cleaning, and guarantees stable quality of the dried material. Additionally, this machine also has the advantages of low off-gas emission and complete removal of the exhaust gas. It is a kind of chemical equipment with high efficiency, low energy consumption and compact structure. Maintenance of the equipment is easy. Paddle Dryer are used for a wide range of application e.g. Agricultural, chemicals, petrochemical, detergents, food products, herbs, s, minerals, metal, pharmaceuticals, Polymers, etc.

As Per The Vira Engineering Design, In The Jacket Shell Body There Are Two Or One Parallel Shafts Which Have Interleaved Paddles. Each Shaft Has Several Fan-Shaped Paddles Which Interleave With Certain Spacing. There Are Two Kinds Of Paddles: Feed Shear Plane And Return Shear Plane, The Shaft Rotates At Low Speed. A Heating Medium Enters The Hollow Rotary Shafts And Paddles Through A Universal Revolving Joint. After Heat Transfer And Drying, It Is Discharged Through The Revolving Joint. The Material Is Continuously Fed Into The Equipment; Next It Is Agitated And Mixed Near The Paddles. At The Same Time, The Material Is Gradually Dried By The Heat Conduction Of Paddle And Jacket. The Height Of Overflow Weir Can Be Changed To Adjust Residence Time. In Addition, Steam Produced In The Drying Process Is Discharged Through The Escape Hole With Trace Amount Of Air. We Can Use All Type Of Energy Media Flow In Jacket Like Electric, Steam, Hot Water, Hot Oil, Cooling Water, All Kinds Of Cooling Media.

Advantages

- It Adopts Conduction Type Of Heat Transfer, The Heat Transfer Efficiency Is High.

- The Self-Cleaning Function Of The Heat Transfer Surface Is Good.

- The Product Quality Is Stable.

- The Material Loss Is Small, The Product Recovery Rate Is High.

- The Material Adaptability Is Broad, The Product Is Dried Evenly.

- It Can Combine Drying And Cooling Together.

- The Equipment With Compact Structure Occupies Small Area.

- The Design Is Unique, And Maintenance Of The Equipment Is Easy.

Product details

|

Frequency [Hz] |

60Hz |

|

Material Grade |

SS304 |

|

Phase |

3 Phase |

|

Power Source |

Electricity |

|

Usage |

Industrial |

|

Voltage [V] |

440 V |

|

Country of Origin |

Made in India |

|

Automation Grade |

Automatic |

|

Material |

Stainless Steel |

|

Capacity |

5Ton |

|

Max Temperature |

500 Degree Centigrade |

|

Brand |

Vira Engineering |

Price 700000.00 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drying Equipment Category

Drum Dryer

Price 600000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Power Consumption : Approx. 510 kW Kilowatt (kW)

Heat Source : Steam / Hot Air

Material : Stainless Steel

Temperature : Up to 200C Celsius (oC)

Rotary Dryer

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Power Consumption : Varies with Capacity (Standard: 18 kW 600 kW) Kilowatt (kW)

Heat Source : Electric / Gas / Oil / Coal

Material : Stainless Steel

Temperature : Up to 300C Celsius (oC)

Belt Dryer

Price 800000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Power Consumption : Approx. 1030 kWh

Heat Source : Electric / Steam / Gas

Material : Stainless Steel

Temperature : Up to 120C

Send Inquiry

Send Inquiry Send SMS

Send SMS