Belt Dryer

Belt Dryer Specification

- Heat Source

- Electric / Steam / Gas

- Power

- 10 kW 30 kW

- Fuel Type

- Electricity / Natural Gas

- Power Consumption

- Approx. 10-30 kWh

- Temperature

- Up to 120C

- Material

- Stainless Steel

- Voltage

- 220V / 380V

- Technology

- Continuous Drying

- Dimension (L*W*H)

- 12000 mm x 2500 mm x 2200 mm

- Moisture Reduction

- Up to 80%

- Control System

- PLC Automatic Control

- Number of Layers

- 15

- Noise Level

- < 75 dB

- Ambient Operating Temperature

- -10C to +45C

- Air Flow Type

- Horizontal / Vertical

- Drying Area

- 2460 m

- Application

- Fruits, Vegetables, Herbs, Chemicals, Biomass

- Belt Material

- Food-grade mesh belt

- Installation Type

- On-site, Modular assembly

- Feeding Capacity

- 500 kg/h 3000 kg/h

- Warranty Extension Option

- Available

- Conveyor Speed Adjustment

- Variable, 0.12 m/min

- Safety Features

- Overload protection, emergency stop

Belt Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 7-20 Days

About Belt Dryer

Belt Dryer

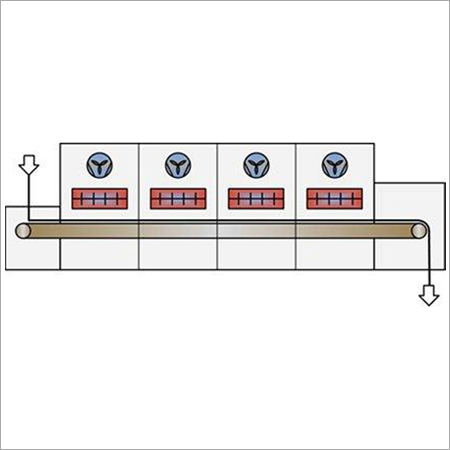

Belt Dryer Is A Continuous Convective Belt Dryer. A Well-Ventilated Layer Of Product Is Put On A Wire Mesh Or Perforated Plate Belt Conveyor And Conveyed Continuously Through Drying Chambers. In These Chambers, Circulating Air Fans Blow Hot Air Through The Product Vertically. In This Process, The Circulating Air Is Reheated After Each Product Flow By The Heat Exchangers Integrated Into The Dryer. The Amount Of Air Required To Discharge The Exhaust Vapor From The Belt Dryer Is Sucked In By A Radial Fan And Fed To The Appropriate Zones Of The Belt Dryer. Due To The Arrangement Of The Air Inlet And Outlet Ducts To And From The Appropriate Zones, The Drying Air Is Passed Repeatedly Through The Product Layer Until It Has The Optimum Vapor Content Before Leaving The Dryer.

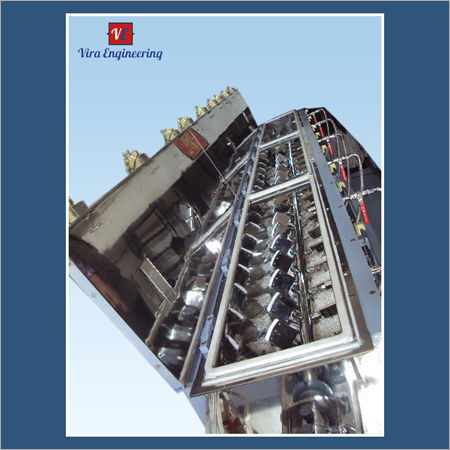

Vira EngineeringS Belt Drying Or Conveyor Drying Systems Are Used In The Chemical And Pharmaceutical Industries, In Food And Stimulants, And For Dyes And Pigments. The Belt Dryer Is Suitable For Drying Free-Flowing, Crumbly, Crystalline, And Lumpy Products, As Well As Malleable Pastes.

Advantages

- Easy Maintenance And Easy- Clean Options With Simple And Efficient Access To All Internal Components

- Easy Operation With A Fully Automatic Control System

- High Thermal Efficiency Due To The Integrated Air Circulation Fans, Thereby Optimizing The Exhaust Air Volume And Heat Recovery From The Dryer Exhaust

- Good Adaptation Of The Temperature Profile To The Drying Behavior Of Different Product Qualities

Advanced Drying Technology for Diverse Applications

Designed using high-quality stainless steel and food-grade mesh belts, this belt dryer is optimized for efficiently drying a wide range of products, including sensitive food items and industrial materials. Its modular setup enables adaptation to production scale and requirements, making it ideal for manufacturers in India seeking reliability and flexibility.

Precision Control and Enhanced Safety

The integrated PLC automatic control system ensures exact temperature and airflow regulation for consistent drying results. Features such as overload protection and emergency stop functions enhance operator and material safety, while variable conveyor speeds (0.12 m/min) allow for adjustable drying outcomes across different production needs.

FAQs of Belt Dryer:

Q: How does the belt dryer achieve moisture reduction up to 80%?

A: The belt dryer utilizes horizontal or vertical airflow and adjustable conveyor speeds to efficiently remove moisture. Its PLC-controlled system ensures precise temperature (up to 120C) and airflow settings, allowing for consistent and thorough drying suitable for a wide range of products.Q: What materials can be processed with this belt dryer?

A: This belt dryer is suitable for drying fruits, vegetables, herbs, chemicals, and biomass. Its food-grade mesh belt and stainless steel construction ensure product safety and hygiene for both edible products and industrial applications.Q: Where can the belt dryer be installed, and what is the installation process?

A: The belt dryer is designed for on-site installation and features a modular assembly, making it adaptable to different production spaces. Installation is managed by the supplier, ensuring proper setup and integration with existing systems.Q: What control and safety features are integrated into the system?

A: The system includes a PLC automatic control for precise adjustments, overload protection to prevent equipment damage, and an emergency stop for immediate shutdown in case of emergencies. These features promote safe operation and protect personnel as well as products.Q: When should the conveyor speed be adjusted, and how does it affect the drying process?

A: Conveyor speed, which is adjustable from 0.1 to 2 m/min, should be set according to the type and moisture content of the material being dried. Slower speeds allow for higher moisture reduction, which is ideal for products requiring thorough drying.Q: What warranty options and after-sales support does the manufacturer offer?

A: The manufacturer provides an initial product warranty with the option to extend coverage for longer periods. Comprehensive after-sales support is available, including technical assistance and parts replacement for continued, reliable operation.

Price 800000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 7-20 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drying Equipment Category

Drum Dryer

Price 600000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Dimension (L*W*H) : Approx. 2.5m x 1.6m x 1.8m Meter (m)

Heat Source : Steam / Hot Air

Voltage : 220/380 V Volt (v)

Rotary Dryer

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Dimension (L*W*H) : Customized / as per requirement Meter (m)

Heat Source : Electric / Gas / Oil / Coal

Voltage : 220/380 V, 50/60 Hz Volt (v)

Send Inquiry

Send Inquiry Send SMS

Send SMS