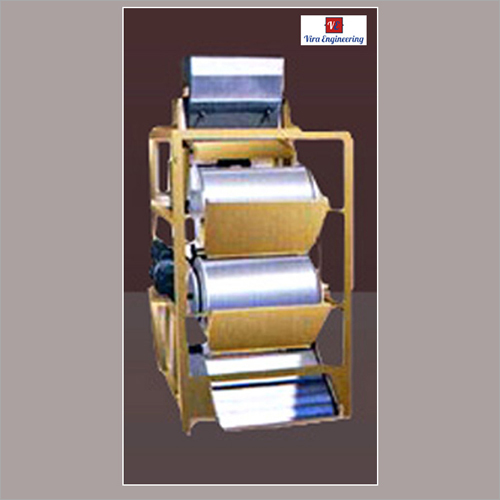

Magnetic Separator

Magnetic Separator Specification

- Frequency

- 50 Hz

- Machine Type

- Industrial Magnetic Separator

- Motor Power

- 2 HP

- Condition

- New

- Noise Level

- Low

- Features

- High magnetic efficiency, easy installation, robust construction, low maintenance.

- Product Type

- Magnetic Separator

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 220-240 V

- Power

- 2 HP

- Power Source

- Electric

- Weight (kg)

- 120 kg

- Dimension (L*W*H)

- 1200 x 500 x 1500 mm

- Capacity

- Up to 10 Ton/hr

- Color

- Blue & Grey

- Usage & Applications

- For separating ferrous materials from non-ferrous material in industries such as mining, recycling, and material handling.

- Magnet Type

- Permanent Ferrite Magnet

- Magnetic Field Strength

- Up to 12000 Gauss

- Conveyor Belt Width

- 300 mm

- Max Operating Temperature

- 80°C

- Discharge Type

- Automatic

- Mounting Type

- Overband / Suspension

Magnetic Separator Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Magnetic Separator

Magnetic Separator

In the Industries recent past the problem of removing the deleterious iron particles from a process stream had a few alternatives. Magnetic separation was typically limited and moderately effective. Magnetic separators that used permanent magnets could generate fields of low intensity only. These worked well in removing ferrous tramp but not fine paramagnetic particles. Thus high-intensity magnetic separators that were effective in collecting paramagnetic particles came into existence. These focus on the separation of very fine particles that are paramagnetic. By mechanism set the different type of magnets and pass the material from this layer and get the ferrous and non ferrous material.

There Are So Many Type Of Magnetic Separators According To The Requirements Of Users, We Can Offer Low, Medium And High Capacity Types Of Magnetic Separators. The Advantages Of This Magnetic Separator Are: Simple Structure, Large Capacity, Easy To Operate And Easy To Maintain There Are So Many Type And Structures As Per Application We Can Use It.

Advantages

- Single, Double, And Triple Drum Magnetic Separator

- High Power Magnetic Roll Separator

- Magnetic Drawer

- Magnetic Chute

- Plate Magnets (For The Conveyor)

- Magnetic Grill

- Inline Magnetic Separator

Product List

- Crushing Equipment

- Grinding Equipment

- Drying Equipment

- Screening Equipment

- Mixing Equipment

- Conveying Equipment

- Pelletizing Equipment

- Kiln

- Separation Equipment

- Feeding Equipment

- Pollution Controlling Equipment

- Storage Equipment

- Erection-Commissioning And R&D Services

Product details

| Material Grade | SS304 |

| Country of Origin | Made in India |

| Phase | Single Phase |

| Frequency | 50 Hp |

| Automation Grade | Automatic |

| Weight | Upto 600 kg |

| Voltage | 240 V |

| Power Source | Electricity |

| Brand | Vira Engineering |

| Material | Mild Steel |

| Usage/Application | Industrial |

| Capacity | 5tons/hr |

High-Efficiency Magnetic Separation

This magnetic separator leverages a permanent ferrite magnet that delivers consistent magnetic field strength up to 12,000 Gauss, ensuring reliable extraction of ferrous metals. It is widely used in industries like mining, recycling, and bulk material processing to maintain product purity and protect downstream equipment from metal damage.

Automatic Operation and Durable Design

Featuring an automatic discharge mechanism and sturdy mild steel build, this separator performs continuous operation with minimal intervention. Its overband or suspension mounting style allows for easy installation in various industrial configurations, while the low-maintenance, robust design ensures long-lasting performance.

Versatility and User-Friendly Operation

With a belt width of 300 mm and capacity of up to 10 tons per hour, this magnetic separator adapts to a variety of material handling applications. Controlled manually without computerized systems, it operates on standard 220240 V electric power, making it accessible for different industrial setups.

FAQs of Magnetic Separator:

Q: How does the automatic discharge function work in this magnetic separator?

A: The automatic discharge system efficiently removes trapped ferrous materials from the magnet belt without manual intervention, enhancing operational convenience and sustaining high throughput during continuous industrial processes.Q: What types of materials can be separated using this equipment?

A: This separator is designed to effectively remove ferrous contaminants from non-ferrous materials, making it ideal for processing minerals, recyclables, and bulk raw materials in industries such as mining, recycling, and material handling.Q: When is it necessary to use an overband or suspension mounted magnetic separator?

A: Overband or suspension mounting is employed when bulk materials need to pass under or through the separator, allowing ferrous contaminants to be captured and automatically discharged, making it suitable for conveyor-based and high-volume operations.Q: Where should this magnetic separator be installed for optimal performance?

A: For best results, the separator should be mounted above conveyor belts where ferrous contaminants are likely to occur. Proper alignment ensures that extracted metals are efficiently separated and discharged away from the material flow.Q: What is the recommended process for installing the magnetic separator?

A: Installation involves securely mounting the unit above the conveyor with appropriate clearances, connecting it to the electric power supply (220240 V), and setting up manual controls. Regular inspection is advised to ensure consistent operation and safety.Q: How can industries benefit from incorporating this magnetic separator in their workflow?

A: By integrating this separator, industries benefit from improved product purity, reduced equipment wear, and minimized downtime. Its high magnetic efficiency and low noise operation deliver cost-effective and reliable solutions for continuous ferrous material removal.

Price 250000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Separation Equipment Category

Density Air Separator

Price Range 200000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual

Automatic Grade : SemiAutomatic

CNC Or Not : Other, No

Capacity : 8001000 kg/hour

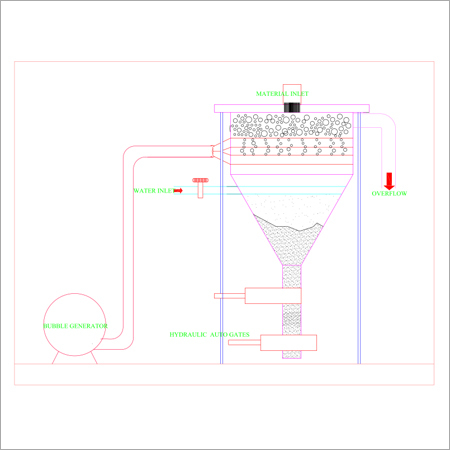

Water Air Bubble Separator

Price Range 200000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual

Automatic Grade : SemiAutomatic

CNC Or Not : Other, No

Capacity : 500 kg/hr

Send Inquiry

Send Inquiry Send SMS

Send SMS