Density Air Separator

Density Air Separator Specification

- Condition

- New

- Motor Power

- 3 HP

- Noise Level

- 68 dB

- Frequency

- 50 Hz

- Features

- High separation efficiency, robust construction, low maintenance

- Machine Type

- Industrial Separator

- Product Type

- Density Air Separator

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- No

- Control System

- Manual

- Voltage

- 380 V

- Power

- 3.5 kW

- Power Source

- Electric

- Weight (kg)

- 850 kg

- Dimension (L*W*H)

- 2200 mm x 1200 mm x 1600 mm

- Capacity

- 800-1000 kg/hour

- Color

- Blue / Yellow

- Usage & Applications

- Separating materials of different densities in recycling, food processing, plastic, grain industries

- Discharge Method

- Manual/Automatic

- Feed Hopper Capacity

- 200 L

- Separator Efficiency

- Up to 99%

- Airflow Rate

- 6000 m/h

- Installation Type

- Floor Mounted

- Protection

- Overload and short-circuit protection

- Working Temperature Range

- -10C to 60C

Density Air Separator Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Density Air Separator

Other Information:

- The powder feeding hopper mounted on the top of the machine.

- The hollow shaft supported by heavy duty bearing which is equipped in the housing

- it consist of one or two disc with whizzer blades.

- The powder distributor disc is fitted bellow lower whizzer hub.

- The Bearing housing, outer and inner drum, deflector vanes, Upper & lower whizzer cones,damper and fine & tail cone are fixed on main body.

The Vira EngineeringS Air Classifier Incorporates A Self-Contained Fan And Rejecter Blade Classification System. Its Internal Fan Design Does Not Require Cyclones, Air Locks Or Dedicated Baghouse For Product Collection Of Particles In The Range Of 60 To 350 Mesh. Completely Self-Contained, Requires No Process Dust-Collection Equipment

Powder Feeding Hopper Mounted On The Top Of Machine. Powder Feeding Tube Is Mounted Co-Axially Inside The Vertical Hollow Shaft. Hollow Shaft Is Supported By Heavy-Duty Bearing Which Is Fitted In Housing. Self-Contained Unit Is Consists One Or Two Disc With Whizzer Blades Rotate Inside Cone. Powder Distributor Disc Is Fitted Bellow Lower Whizzer Hub. Top Chamber Consists Rotating Deflector Blades. Whizzer Blades, Distributor Plates, And Deflector Blades Are Driven By Motor And Produce The Internal Air Circuit. Bearing Housing, Outer & Inner Drum, Damper, Deflector Vanes, Upper & Lower Whizzer Cones And Fine & Tail Cone Are Fixed On Main Body.

Centrifugal Type Closed Circuit Air Classifier Is To Separate Dry Powder Into Coarse & Fine Powder. Powder Can Be Separated Are From 60-350 Mashes. It Removes Coarser Particles Like Free Iron, Their Oxides, Grit, Silica, Heavy Impurities. Alternatively, It Can Remove Fine/Light Foreign Material As To De-Dust A Product. Deflector Blades Produce Centrifugal Force And Air Current To Separate Particles And Impurities On Weight Basis.

Classifier Is For Getting Uniform Size Of Powder At Out-Let. Any Powder Is Fed In Classifier Will Separate It Into Coarse And Fine Powder. It Is Not Grinding Any Material. Types Of Material Are Classified Like Cement, Flour, Chemicals, Pigments, Food Colors, Minerals, Sand, Zinc, Phosphors , Etc.

Product details

| Alignment | Vertical |

| Automation Grade | Automatic |

| Brand | Vira Engineering |

| Color | Blue |

| Frequency | 60 Hz |

| Power Source | Electricity |

| Surface Finish | Color Coated |

| Usage | Industrial |

| Voltage | 440 V |

| Country of Origin | Made in India |

Superior Separation Efficiency

Achieve up to 99% separator efficiency with advanced airflow technology that distinguishes materials based on density. The 6000 m/h airflow rate ensures rapid and thorough processing, maximizing productivity for industrial applications while maintaining consistent results.

Durable Construction & Safety

Manufactured from robust mild steel and protected with overload and short-circuit safeguards, this air separator delivers exceptional reliability. Its floor-mounted design and semi-automatic operation make it a dependable choice for continuous operations in challenging industrial settings.

Versatile Industrial Applications

This separator is ideal for various industries, including recycling, food processing, plastics, and grains. It simplifies the process of separating mixed materials of different densities, enabling efficient waste management, improved product purity, and streamlined manufacturing workflows.

FAQs of Density Air Separator:

Q: How does the density air separator function in material separation processes?

A: The density air separator uses a controlled airflow of up to 6000 m/h to separate materials based on their density. As mixed materials enter via the 200 L feed hopper, lightweight and heavy particles are separated effectively, achieving a separator efficiency of up to 99%.Q: What kinds of industries can benefit from using this air separator?

A: Industries such as recycling, food processing, plastics, and grain production frequently use this density air separator to sort materials, remove contaminants, and increase the purity and quality of final products.Q: When should the separators discharge method be set to manual versus automatic?

A: The discharge method can be selected based on operational requirements: use manual discharge for smaller batches or precise control, and automatic discharge for continuous high-volume separation to boost productivity.Q: Where should the separator be installed for optimal performance?

A: This floor-mounted air separator should be placed in a stable, well-ventilated industrial area with access to an electric power supply (380 V, 50 Hz), ensuring ample space for the units 2200 mm x 1200 mm x 1600 mm footprint.Q: What maintenance does the separator require?

A: Regular cleaning of the feed hopper and airflow passages, along with routine checks of the mild steel frame and motor, are recommended. Thanks to its durable construction and overload protection, maintenance requirements are minimal.Q: How does using this separator benefit industrial processes?

A: By reliably separating mixed materials, the separator enhances process efficiency, reduces labor, minimizes product contamination, and helps industries achieve higher output quality with lower operating costs.Q: What safety features are integrated into the density air separator?

A: The separator is equipped with overload and short-circuit protection systems, ensuring safe and continuous operation even under demanding industrial conditions.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Separation Equipment Category

Magnetic Separator

Price 250000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Frequency : 50 Hz

Capacity : Up to 10 Ton/hr

Voltage : 220240 V

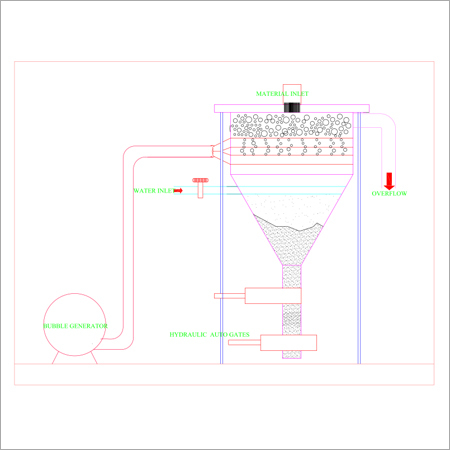

Water Air Bubble Separator

Price Range 200000.00 - 1000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50/60 Hz

Capacity : 500 kg/hr

Voltage : 220V

Send Inquiry

Send Inquiry Send SMS

Send SMS