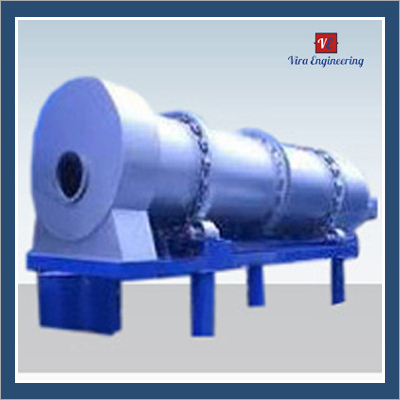

Fertilizer Drum Granulator

Fertilizer Drum Granulator Specification

- Dosage

- Depends on production capacity requirements

- Classification

- Fertilizer Processing Machinery

- Chemical Name

- Fertilizer Drum Granulator

- Other Names

- Rotary Drum Granulator, Compound Fertilizer Granulator

- Type

- Processing Equipment

- Physical State

- Solid (Equipment)

- Release Type

- Controlled Release

- Purity(%)

- 99%

- Application

- NPK Compound Fertilizer Granulation

- Color

- Blue / Green (Body)

- Solubility

- Insoluble (Granulating Process)

- Storage

- Store in dry, ventilated area away from corrosive materials

- Granule Size Range

- 2mm - 6mm

- Feeding Material

- Powder or small particles

- Discharge Mode

- Automatic

- Rotating Speed

- 3.5 - 7.5 r/min

- Production Capacity

- 1-20 TPH (Adjustable)

- Drum Length

- 2m - 7m (Model Specific)

- Power Requirement

- 22-90 kW (Model Dependent)

- Drum Diameter

- 1m - 3.2m (Model Specific)

- Usage Environment

- Indoor industrial workshops

- Material of Construction

- Carbon Steel / Stainless Steel (Optional)

- Control System

- Fully Automatic / Semi-Automatic

- Maintenance

- Low maintenance, easy to operate

- Moisture Content for Granulation

- 2% - 8%

- Installation

- On-site installation available

- Weight

- 2-15 Tons (Depending on Model)

- Granulation Rate

- Over 95%

- Packaging

- Standard export packing

- Service Life

- >10 Years with proper maintenance

Fertilizer Drum Granulator Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Fertilizer Drum Granulator

Drum Granulator belongs to key fertilizer granulating equipment for making compound fertilizer granules. It can be applied to both cold and heat granulation with high medium and large scale production. It can make both low & high concentrations of compound fertilizer granules. The finish inside the drum is made by resistance rubber sheet. Moreover, Drum Granulator is known for its rust resistance, low energy consumption, easy operation and maintenance.

Rotary Granulator Belongs To One Of The Key Fertilizer Granulating Equipment For Making Compound Fertilizer Granules. Which Is Applyed To Both Cold And Heat Granulation With High, Medium And Large Scale Production.

The Granulating Method Is Rolling Round Particles In Wet Granulation. With Water Or Vapor Added Material In To Drum, The Material In Rotary Drum Are Blended Uniformly And Become Humid, During This Process, The Material Reacts And By Way Of The Liquid Environment And Rotation In Drum, The Material Particles Squeeze Each Other And Roll Into Particles. The Formed Particles Are Of 3-4Mm.

Advantages

- Large Granulating Capacity, Low Energy Consumption And Low Maintenance Cost.

- Flexible Fertilizer Particles Diameter According To Different Formulation, Processing Procedure And Raw Materials.

- Super Quality Steel Materials, Strict Quality Requirements And Control.

- Low Noise, Stable Performance Rational Structure Like Shoveling Plates To Clean Drums.

Product List

- Crushing Equipment

- Grinding Equipment

- Drying Equipment

- Screening Equipment

- Mixing Equipment

- Conveying Equipment

- Pelletizing Equipment

- Kiln

- Separation Equipment

- Feeding Equipment

- Pollution Controlling Equipment

- Storage Equipment

- Erection-Commissioning And R&D Services

Product details

| Country of Origin | Made in India |

| Capacity | 2 Ton Per Hour |

| Material | Stainless Steel |

| Brand | Vira Engineering |

| Driven Type | Geared Motor |

| Frequency | 60 Hz |

| Phase | 3 Phase |

| Rotary Speed | 6 RPM |

| Voltage | 440 V |

| Automation Grade | Semi-Automatic |

Reliable Granulation Performance

Achieve a granulation rate of over 95% with the Fertilizer Drum Granulator, ensuring minimal waste and high product consistency. The adjustable rotating speed between 3.5 and 7.5 r/min enables precise control over granule formation. This makes it an ideal choice for NPK compound fertilizer production, supporting a granule size range from 2mm to 6mm.

Durable Construction and Long Service Life

Crafted from high-quality carbon steel or optional stainless steel, this granulator withstands rigorous industrial use. With a projected service life of over 10 years when properly maintained, it also boasts low maintenance requirements. The equipment is built to resist corrosion and can be tailored to meet specific production needs.

Flexible Operation and Easy Installation

Installation services are available on-site, ensuring seamless integration into existing production lines. The drum granulator supports both fully automatic and semi-automatic control options, catering to varying operational preferences. Automatic discharge and standard export packaging further simplify usage and logistics.

FAQs of Fertilizer Drum Granulator:

Q: How does the Fertilizer Drum Granulator process fertilizer materials?

A: It processes powder or small particle feed materials by continuously rotating the drum, where materials are moistened and agglomerated into uniform granules using controlled speed, moisture content (2%8%), and adjustable capacity.Q: What are the advantages of using a drum granulator for NPK compound fertilizer production?

A: The drum granulator offers high granulation rates (over 95%), controlled granule size (2mm6mm), low maintenance needs, robust construction, and customizable operation, ensuring consistent quality and efficiency in fertilizer production.Q: When is on-site installation available for this machinery?

A: On-site installation is available upon purchase, and a manufacturers technician will visit your industrial workshop to install and commission the equipment, ensuring correct setup and operation.Q: Where should the drum granulator be installed for optimal performance?

A: The equipment is designed for indoor use in well-ventilated, dry industrial workshops, away from corrosive substances, to ensure operational safety and extended service life.Q: What control systems are provided with this drum granulator?

A: The granulator supports both fully automatic and semi-automatic control systems, allowing users to select the mode that best fits their production requirements and management preferences.Q: How should the Fertilizer Drum Granulator be maintained for a service life over 10 years?

A: Routine inspections, lubricating moving parts, cleaning after use, and timely replacement of worn components will ensure low maintenance and extend its service life beyond 10 years.Q: What benefits can users expect from choosing this equipment?

A: Users benefit from efficient and consistent granulation, improved production output, long-lasting performance, straightforward operation, and customizable features suited to varying fertilizer production needs.

Price 1000000 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

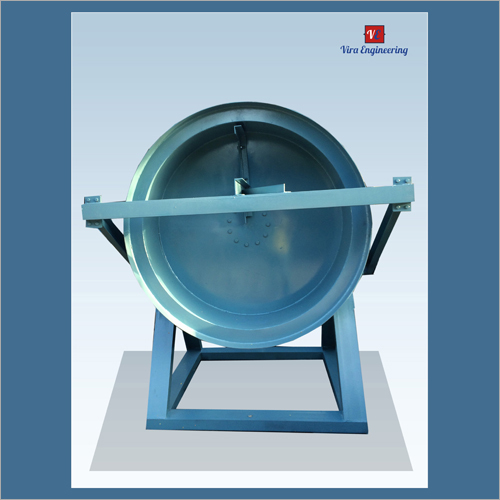

More Products in Pelletizing Equipment Category

Disk Type Pelletizers

Price 400000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Chemical Name : Other, Disk Type Pelletizer

Classification : Other, Industrial Machinery

Storage : Store in dry, clean area

Type : Other, Granulation Equipment

Send Inquiry

Send Inquiry Send SMS

Send SMS