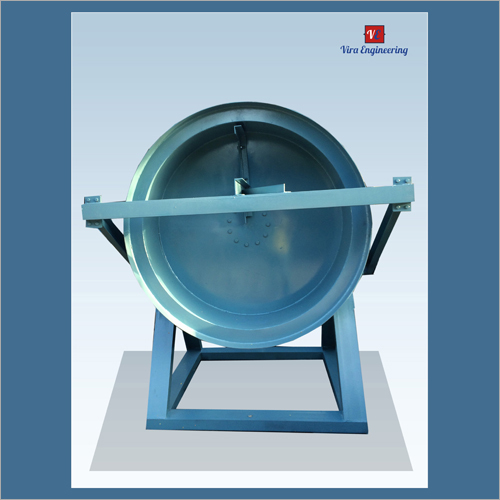

Disk Type Pelletizers

Disk Type Pelletizers Specification

- Dosage

- As per process requirement

- Classification

- Industrial Machinery

- Chemical Name

- Disk Type Pelletizer

- Other Names

- Disc Granulator, Pan Pelletizer

- Type

- Granulation Equipment

- Physical State

- Solid Equipment

- Release Type

- Continuous

- Application

- Pelletizing powders in fertilizer, chemical, metallurgical industries

- Color

- Metallic Grey

- Storage

- Store in dry, clean area

Disk Type Pelletizers Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Disk Type Pelletizers

Disk Type Pelletizers

Vira Engineering Owing To Rich Industrial Experience, We Manufacturing And Supply A Quality Tested Assortment Of Pelletizers. These Products Undergo Strict Quality Checks Before Being Introduced In The Market. The Offered Products Are Made Accordingly To Meet The Requirements Of Clients. Besides This, We Ensure Our Prestigious Clients To Deliver These Product In Committed Time Frame.

The Rotating Pan Is Mounted On A Tilting Frame. Material Is Fed From Above Through A Pipe. Pelletizing Liquid Is Sprayed Through Nozzles Mounted On A Movable Manifold .Pellets Are Formed By The Rolling Motion Of Material In The Pan And The Liquid Spray. Pellet Size Is Determined By Pan Inclination, Amount Of Liquid And Other Parameter. The Rolling Motion Causes The Larger Pellets To Rise To The Surface And Discharge Continuously Over The Pan Rim Into A Discharge Chute.

Pelletizers Can Agglomerate Fine, Dry Feed Materials Such As Chemical Powders, Limestone, Fertilizer, Coal Fines, Cement / Lime Kiln Dust And Fly Ash As Well As Wetter Materials Such As Filter / Centrifuge Cake, Minerals, Ores, Vibrating Sludge And Pond Tailings.

Advantages

- Easy Maintenance

- Pan Inclination Can Be Fixed In Any Position

- Manually Or Motor Actuated Pan Tilt Mechanism

- Pan Floor Cleaned By Rotating Scrapers

- Wall And Rim

- Pan With Varying Wall Height And Stepped Wall For Powdering Off

- Available With Infinitely Variable Pan Speeds

- Special Materials Of Construction Available

- Pan Equipped With Dust Hood And Exhaust Connections

Product details

| Automation Grade | Semi Automatic |

| Disc Size | 375mm dia |

| Frequency | 50Hz |

| Material Grade | SS304 |

| Surface Finish | Color Coated |

| Usage/Application | Industrial |

| Voltage | 440V |

| Country of Origin | Made in India |

| Material | Stainless Steel |

| Production Capacity | 500 kg/hr |

| Power Consumption | 5 Hp |

| Brand | Vira Engineering |

Versatile and Customizable Granulation Equipment

Disk Type Pelletizers are engineered to deliver flexibility through a range of customizable features, such as disc diameter, liner options, drive systems, and feeding methods. This adaptability ensures seamless application across various industries, including fertilizers, chemicals, and metallurgy, meeting specific production needs with efficiency and precision.

Robust Construction and High Performance

Constructed from high-quality Mild Steel or Stainless Steel, each pelletizer is built to withstand demanding industrial environments. The adjustable disc inclination and gear motor drive contribute to consistent pellet quality, while options for anti-corrosive coatings provide longevity and reduced maintenance.

Effortless Operation and Installation

Designed for both automatic and semi-automatic operation modes, Disk Type Pelletizers simplify the pelletizing process. The inclusion of on-site installation assistance further guarantees smooth setup, allowing operators to maximize productivity while minimizing downtime.

FAQs of Disk Type Pelletizers:

Q: How does the Disk Type Pelletizer work to form pellets?

A: The Disk Type Pelletizer utilizes a rotating inclined disc to agglomerate fine powders. As the disc spins, materials are fed either manually or through an automated system, forming uniform pellets through layering as they roll along the discs surface. Adjustable inclination ensures optimal pellet shape and size.Q: What materials and industries are best suited for this equipment?

A: This pelletizer is ideal for granulating powders in fertilizer, chemical, and metallurgical industries. It is capable of processing a variety of raw materials, thanks to its robust construction in Mild Steel or Stainless Steel and customizable options for liners and drive systems.Q: When should I choose manual versus automated feeding for my pelletizer?

A: Manual feeding is suitable for smaller-scale or test applications where flexibility is required, while automated feeding is recommended for continuous, high-capacity operations to ensure consistent throughput and reduce labor requirements.Q: Where should I install and store the Disk Type Pelletizer for optimal performance?

A: Install the equipment in a dry, clean industrial environment with adequate space for operation and maintenance. For storage, ensure the area is free from moisture and debris to prevent corrosion and preserve surface coatings.Q: What benefits does adjustable disc inclination provide during the pelletizing process?

A: Adjustable disc inclination allows operators to fine-tune the pelletizing angle according to material characteristics and desired pellet size, resulting in improved pellet uniformity, enhanced product quality, and increased production efficiency.Q: How can the Disk Type Pelletizer be customized to fit my process requirements?

A: You can tailor your pelletizer with custom disc diameters, various liner materials for enhanced durability, preferred drive systems, and feeding methods to align with your specific process demands and capacity goals.

Price 400000.00 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pelletizing Equipment Category

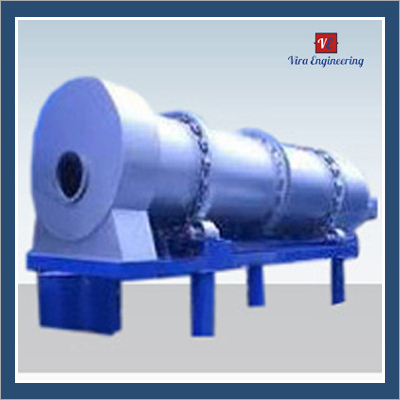

Fertilizer Drum Granulator

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Purity(%) : 99%

Chemical Name : Other, Fertilizer Drum Granulator

Physical State : Other, Solid (Equipment)

Color : Other, Blue / Green (Body)

Send Inquiry

Send Inquiry Send SMS

Send SMS