Dust Collection Unit

Dust Collection Unit Specification

- Instruments Type

- Dust Collector

- Sensor Type

- Particle Sensor

- Measurement

- Particulate Concentration

- Usage & Applications

- Industrial Air Cleaning, Workshop, Factories

- Automation Grade

- Semi-Automatic

- Power Source

- Electric

- Orientation

- Vertical

- Display Type

- Analog

- Efficiency

- >99%

- Temperature

- Up to 50C

- Air Flow

- 5000 CFM

- Product Type

- Industrial Dust Collection Unit

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 75 dB

- Reactor Thickness

- 5 mm

- Processing Time

- Continuous Operation

- Capacity

- 5000 m/hour

- Voltage

- 220-240 V

- Weight

- Approx. 300 kg

- Dimension (L*W*H)

- 1200 x 1000 x 2150 mm

- Surface

- Powder Coated

- Mobility

- Fixed (Castor Wheel optional)

- Filter Type

- Bag Filter

- Motor Power

- 5 HP

- Dust Discharge Method

- Manual Tray

- Inlet Diameter

- 300 mm

- Number of Bags

- 18 Nos.

- Installation

- Floor Mounted

- Cleaning Mechanism

- Manual Shaking

- Color

- Industrial Grey

- Control Panel

- Included

Dust Collection Unit Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Dust Collection Unit

Dust Collection Unit

A Cyclone & Dust Collector Is A System Used To Enhance The Quality Of Air Released Or Pre-Separators From Industrial And Commercial Processes By Collecting Dust And Other Impurities From Air Or Gas. Designed To Handle High-Volume Dust Loads, A Dust Collector System Consists Of A Blower, Dust Filter, A Filter-Cleaning System, And A Dust Receptacle Or Dust Removal System. It Is Distinguished From Air Cleaners, Which Use Disposable Filters To Remove Dust.

Dust Collectors Are Used In Many Processes To Either Recover Valuable Granular Solid Or Powder From Process Streams, Or To Remove Granular Solid Pollutants From Exhaust Gases Prior To Venting To The Atmosphere. Dust Collection Is An Online Process For Collecting Any Process-Generated Dust From The Source Point On A Continuous Basis. Dust Collectors May Be Of Single Unit Construction, Or A Collection Of Devices Used To Separate Particulate Matter From The Process Air. They Are Often Used As An Air Pollution Control Device To Maintain Or Improve Air Quality.

Fume And Smoke Collectors Are Used To Remove Sub-Micrometer-Size Particulates From The Air. They Effectively Reduce Or Eliminate Particulate Matter And Gas Streams From Many Industrial Processes Such As Welding, Rubber And Plastic Processing, High Speed Machining With Coolants, Tempering, And Quenching.

Vira EngineerS Cyclone Dust Collector Also Called The Centrifugal Dust Collector, It Is Mainly In Ventilation Dust Removal And Material Recycling System Of Mining, Metallurgy, Refractory, Coal, Chemical And Electric Power Industries, Especially Suitable For The Initial Purification For High Temperature Flue Gas.

There Are Various Size And Type Of Cyclone Dust Collector Unit For Pre-Separators And Dust Free Air Realize As Per Applicable We Are Offer It.

A Cyclone & Dust Collector Is A System Used To Enhance The Quality Of Air Released Or Pre-Separators From Industrial And Commercial Processes By Collecting Dust And Other Impurities From Air Or Gas. Designed To Handle High-Volume Dust Loads, A Dust Collector System Consists Of A Blower, Dust Filter, A Filter-Cleaning System, And A Dust Receptacle Or Dust Removal System. It Is Distinguished From Air Cleaners, Which Use Disposable Filters To Remove Dust.

Dust Collectors Are Used In Many Processes To Either Recover Valuable Granular Solid Or Powder From Process Streams, Or To Remove Granular Solid Pollutants From Exhaust Gases Prior To Venting To The Atmosphere. Dust Collection Is An Online Process For Collecting Any Process-Generated Dust From The Source Point On A Continuous Basis. Dust Collectors May Be Of Single Unit Construction, Or A Collection Of Devices Used To Separate Particulate Matter From The Process Air. They Are Often Used As An Air Pollution Control Device To Maintain Or Improve Air Quality.

Fume And Smoke Collectors Are Used To Remove Sub-Micrometer-Size Particulates From The Air. They Effectively Reduce Or Eliminate Particulate Matter And Gas Streams From Many Industrial Processes Such As Welding, Rubber And Plastic Processing, High Speed Machining With Coolants, Tempering, And Quenching.

Vira EngineerS Cyclone Dust Collector Also Called The Centrifugal Dust Collector, It Is Mainly In Ventilation Dust Removal And Material Recycling System Of Mining, Metallurgy, Refractory, Coal, Chemical And Electric Power Industries, Especially Suitable For The Initial Purification For High Temperature Flue Gas.

There Are Various Size And Type Of Cyclone Dust Collector Unit For Pre-Separators And Dust Free Air Realize As Per Applicable We Are Offer It.

- Single Cyclone And Dust Collector Unit

- Multi Cyclone Unit (For Separation)

- Mobile Dust Collection Unit.(For Material Handling Unit)

- Cylinder Type Dust Collection Unit

- Square Type Bag Filter Unit,

- Pulse Jet Dust Collector.

- Jacket Type Cyclone And Dust Collector,

Product details

| Capacity | 5Ton |

| Material Grade | SS304 |

| Power Source | Electricity |

| Frequency (Hz) | 60Hz |

| Voltage (V) | 440V |

| Country of Origin | Made in India |

| Automation Grade | Fully Automatic |

| Material | Stainless Steel |

| Surface | Color Coated |

| Usage | Industrial |

| Brand | Vira Engineering |

High-Efficiency Air Cleaning for Industrial Settings

Designed to deliver reliable performance in workshops, factories, and other industrial environments, this dust collection unit offers a substantial capacity of 5000 m/hour. Its advanced bag filter system ensures particulate matter is effectively captured, providing clean air and improved workplace safety. Crafted from mild steel with a 5 mm thick reactor, the unit supports demanding, continuous operation with impressive durability and efficiency exceeding 99%.

User-Friendly Operation and Maintenance

Operating this dust collector is straightforward thanks to its analog control panel and semi-automatic controls. Manual shaking keeps the bag filters clean, while dust can be removed easily via a manual tray. The fixed orientation is ideal for floor-mounted setups, with castor wheels available for added flexibility. Maintenance is simplified, ensuring minimal downtime and optimal dust extraction at all times.

FAQs of Dust Collection Unit:

Q: How does the dust collectors bag filter and manual shaking mechanism enhance air cleaning efficiency?

A: The 18-bag filtration system, combined with a manual shaking mechanism, ensures efficient dust capture and filter cleaning. Regular manual shaking dislodges accumulated dust, which is then collected in the manual tray, maintaining consistent airflow and high filtration efficiency of over 99%.Q: What types of environments and applications is this dust collection unit best suited for?

A: This dust collector is ideal for industrial settings such as workshops, manufacturing plants, and factories where effective particulate control is essential, and air quality must comply with industry standards. Its robust construction and high airflow capacity make it suitable for continuous operation in demanding conditions.Q: When should the dust discharge tray be emptied and the filters cleaned?

A: The dust discharge tray should be emptied regularly, depending on the dust load and operating hours. Bag filters ought to be manually shaken after each operating cycle or when reduced airflow is noticed, ensuring optimal collector performance and preventing filter clogging.Q: Where should the dust collector be installed for best performance?

A: For optimal results, the unit should be floor-mounted in a centralized location within your facility, away from moisture and excessive heat. Proper positioning ensures maximum dust capture from emission sources and stable operation, with the option to add castor wheels for flexible placement if needed.Q: What is the process for operating and maintaining this dust collection unit?

A: The operator switches on the unit through its control panel, allowing dust-laden air to enter via the 300 mm inlet. Collected dust is trapped on the filter bags; shaking the bags periodically removes this dust, which settles into the manual tray for easy disposal. Routine inspection and cleaning maintain the units reliability and longevity.Q: How does this dust collector benefit workplaces and workers?

A: By consistently capturing particulate matter at high efficiency, the unit protects machinery, improves respiratory health for workers, and ensures compliance with air quality standards. Its quiet operation, robust construction, and easy maintenance contribute to a safer, more productive work environment.

Price 500000.00 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pollution Controlling Equipment Category

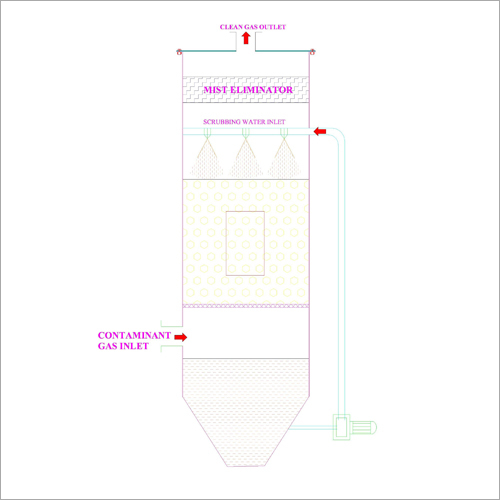

Wet Scrubber Systems

Price 400000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wet Scrubber Systems

Voltage : 440 V Volt (v)

Material : Mild Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS