Rotary Dryer

Rotary Dryer Specification

- Power

- 20-125 HP Horsepower (HP)

- Heat Source

- Electric / Gas / Oil / Coal

- Fuel Type

- Electricity, Diesel, Gas, Coal

- Power Consumption

- Varies with Capacity (Standard: 18 kW 600 kW) Kilowatt (kW)

- Temperature

- Up to 300C Celsius (oC)

- Material

- Stainless Steel

- Voltage

- 220/380 V, 50/60 Hz Volt (v)

- Technology

- Direct or Indirect Heating

- Dimension (L*W*H)

- Customized / as per requirement Meter (m)

Rotary Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Rotary Dryer

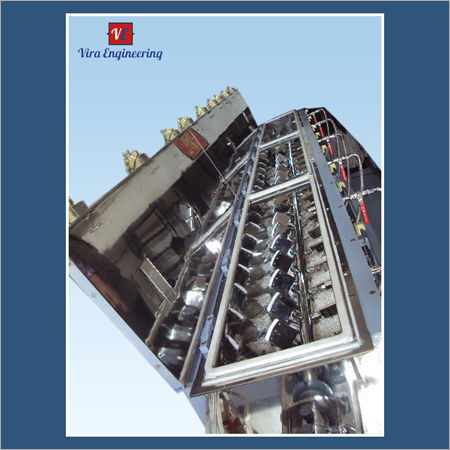

Rotary Dryer

Vira Engineering S Rotary Dryer Is A Type Of Industrial Dryer Employed To Reduce Or Minimize The Liquid Moisture Content Of The Material It Is Handling By Bringing It Into Direct Contact With A Heated Gas. Rotary Dryer Is Suitable To Dry Metallic And Nonmetallic Mineral, Clay In Cement Industrial, Chemicals, Foods, Fertilizer And Coal Mine, Etc.

The Dryer Is Made Up Of A Rotating Cylindrical Tube, Usually Supported By Steel Structure. The Dryer Slopes Slightly So That The Discharge End Is Lower Than The Material Feed End In Order To Convey The Material Through The Dryer Under Gravity Or By Lifter/Screw. When The Wet Material Is In The Process Of Moving Forward In The Rotary Dryer Cylinder Body, The Lifting Plates Inside The Rotary Dryer Cylinder Makes The Material Up And Down To Contact With The Hot Flue Gas Completely. The Moisture Inside The Wet Material Is Evaporated Into Water Vapors, And Finally We Get The Dried Materials. This Gas Stream Is Move Co-Current Flow,

Vira Engineering S Giving The Heat Energy By Auto Combustion Burner. We Have All Auto Controller For The Firing System So We Can Operate It Easily And Safely Like Fuel Flow, Ignition, Temperature Controlling, Flame Air Controlling, Emergency And Auto On/Off Ext. We Can Use Any Type Of Fuel Or Gas For Direct Or Indirect Firing.

Advantages

- High Mechanization, Strong Production Capability And Continuous Operation,

- Simple Structure, Convenient Operation,

- Low Malfunction, Low Maintenance Cost.

- Wide Application Range And Good Drying Effect

Product details

|

Frequency |

50 Hz |

|

Power Source |

Electricity |

|

Usage |

Industrial |

|

Country of Origin |

Made in India |

|

Automation Grade |

Automatic |

|

Material Grade |

SS304 |

|

Heating Resource |

Biomass Pellets |

|

Voltage |

440V |

|

Material |

Stainless Steel |

|

Brand |

Vira Engineering |

|

Capacity |

5 ton/hr |

Versatile Drying Applications

The rotary dryers broad capacity and robust construction allow it to handle a variety of industrial processes. It is ideally suited for drying minerals, chemicals, food products, pharmaceuticals, and agricultural outputs, meeting the specific moisture removal needs of each sector. With customizable drum sizes and installation types, this dryer ensures optimal drying efficiency for unique material properties.

Flexible Automation and Control

Available in both semi-automatic and automatic variants, the rotary dryer integrates modern digital or PLC-based control panels for precise monitoring of drying parameters. These advanced options streamline operation and enhance process consistency, while optional exhaust systemssuch as cyclone, scrubber, and bag filterssupport clean, safe working environments.

FAQs of Rotary Dryer:

Q: How does the rotary dryer improve the drying process for different materials?

A: The rotary dryer enhances drying efficiency by providing adjustable drum dimensions and operation modes, accommodating various feed sizes and moisture levels. Its customizable settings and optional exhaust systems facilitate consistent, thorough moisture removal for minerals, chemicals, food, and pharmaceutical products.Q: What types of products can be processed using this rotary dryer?

A: This rotary dryer is capable of drying a wide range of products, including minerals, chemicals, food items, pharmaceutical ingredients, and agricultural commodities, making it suitable for diverse industrial applications.Q: When should I opt for the automatic control panel on the rotary dryer?

A: The automatic digital or PLC-based control panel is recommended when precise process control and operational consistency are critical, especially for larger batch sizes or sensitive materials that require exact moisture regulation.Q: Where is the rotary dryer typically installed, and are there alternative configurations?

A: The rotary dryer is usually installed in a horizontal orientation within industrial facilities. For specific operational needs, an inclined design is also available, providing flexibility for different site layouts and material properties.Q: What is the process capacity and maximum feed size for this rotary dryer model?

A: This rotary dryer offers a capacity range from 0.5 to 50 tons per hour and can process feed materials up to 40 mm in size, supporting efficient operations for small-scale to large-scale drying requirements.Q: How does the exhaust system benefit the usage of rotary dryer?

A: Optional exhaust systems, including cyclone separators, scrubbers, and bag filters, help capture and manage airborne particles and moisture, improving environmental safety, maintaining air quality, and ensuring compliance with industry standards.Q: What are the main advantages of using this rotary dryer in industrial settings?

A: Key benefits include customizable drying solutions, efficient moisture control, reliable build quality, versatile automation options, and enhanced safety features, all contributing to improved productivity and reduced operational costs for manufacturers and suppliers across India.

Price 1000000 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 15 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drying Equipment Category

Drum Dryer

Price 600000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Heat Source : Steam / Hot Air

Fuel Type : Electric / Gas / Diesel options

Power : 7.5 HP Horsepower (HP)

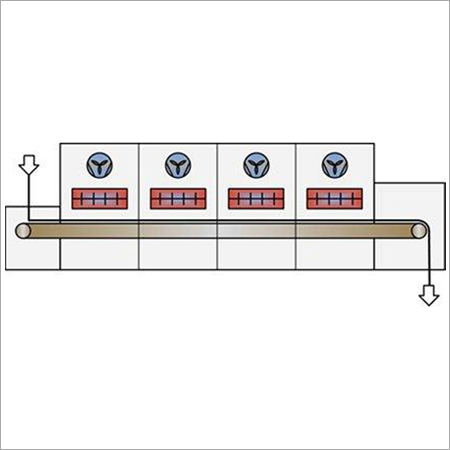

Belt Dryer

Price 800000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Heat Source : Electric / Steam / Gas

Fuel Type : Electricity / Natural Gas

Power : 10 kW 30 kW

Send Inquiry

Send Inquiry Send SMS

Send SMS