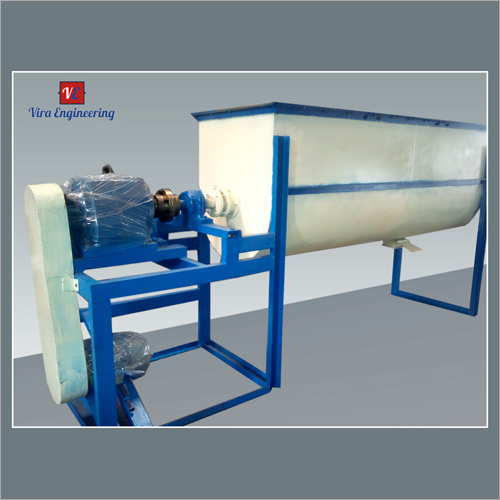

Paddle Mixer

Paddle Mixer Specification

- Lifting Height

- 1.2 m

- Lifting Speed

- Up to 1.5 m/min

- Motor Power

- 5 HP

- Surface

- Polished, rust-resistant

- Product Type

- Paddle Mixer

- General Use

- Mixing of powders, granules, chemicals, or food ingredients

- Material

- Stainless Steel

- Type

- Horizontal Batch Mixer

- Capacity

- 500 Litres

- Weight (kg)

- 350 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Control System

- Manual/Panel operated

- Method

- Agitation and blending by paddles

- Voltage

- 415 V, 50 Hz

- Dimension (L*W*H)

- 1850 x 950 x 1350 mm

- Feature

- High-efficiency mixing, easy cleaning, robust construction

- Color

- Metallic silver

- Maintenance

- Low, easy access to components

- Application Industries

- Pharmaceutical, Food, Chemical, Agricultural

- Operating Temperature Range

- 5C to 50C

- Mobility

- Mounted on wheels for ease of movement

- Safety Feature

- Overload protection, safety lock lid

- Drive Type

- Electric motor with gear reduction

- Sealing

- Dust & splash-proof covers

- Discharge Type

- Bottom discharge with manual lever

- Number of Paddles

- 8

- Mixing Cycle Time

- 1020 minutes (per batch)

- Noise Level

- < 75 dB

Paddle Mixer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

About Paddle Mixer

- Single Shaft Paddle Mixer

- Double Shaft Paddle Mixer

It Useful For Mixing Bio Waste, Tar, Fertilizer, Starch, Pharmaceuticals, Animal Feeds, Agro Chemicals, Chemicals, Minerals, Minerals, Paints, Polymers, Dust Etc Product.

Advantages

- Low Operational Speed

- High Mixing Efficiency

- No Separation Over A Long Mixing Duration.

- Liquid Addition Possible

- Short Mixing Time And High Homogeneity.

- Widely Used For The Pre-Mix, Feed Industry And Pharmaceutical Industry.

- Quick Discharge With Minimal Residue, Thanks To A Full Length Discharge Gate

- Very Less Heat Is Generated.

Product details

| Material Grade | SS304 |

| Surface Finish | Polished |

| Country of Origin | Made in India |

| Material | Stainless Steel |

| Frequency | 50Hz |

| Phase | 3 Phase |

| Driven Type | Electric |

| Voltage | 440V |

| Brand | Vira Engineering |

| Capacity | 300kg |

Precision Mixing for Diverse Applications

Engineered for batch processing, this paddle mixer facilitates uniform agitation and blending of powders, chemicals, or food ingredients. Its stainless steel build ensures hygienic, corrosion-resistant operation essential for pharmaceutical and food production, while high-capacity (500 litres) design accommodates large-scale manufacturing needs.

Robust Construction, Smooth Operation

The mixers noise output remains below 75 dB, making it ideal for sensitive work environments. Equipped with a 5 HP electric motor and gear reduction, it guarantees consistent performance through every cycle. Reliable dust and splash-proof seals protect both operator and material integrity during use.

Enhanced Mobility and Safety

Fitted with sturdy wheels, this batch mixer is easy to maneuver within production spaces. It includes safety features such as an overload protection system and safety lock lid that minimize risk during operation. Maintenance is minimal thanks to accessible components and easy-to-clean surfaces.

FAQs of Paddle Mixer:

Q: How does the paddle mixer ensure efficient blending of various materials?

A: The mixer utilizes eight precisely arranged paddles for thorough agitation, ensuring uniform mixing of powders, granules, chemicals, or food ingredients in each batch. The electric motor with gear reduction provides steady power for consistent results.Q: What industries and applications is this mixer suitable for?

A: It is ideal for pharmaceutical, food processing, chemical, and agricultural industries, handling applications that require the homogenous mixing of dry or moist ingredients, chemicals, or granular materials.Q: When should I use the bottom discharge and manual lever feature?

A: After the mixing cycle is complete (usually within 1020 minutes per batch), use the manual lever to open the bottom discharge. This enables efficient unloading of the mixed product while reducing spillage and contamination risks.Q: Where can the mixer be easily relocated within a facility?

A: Mounted on durable wheels, the mixer can be moved effortlessly across different parts of your processing area, allowing greater flexibility in workspace organization and easy transfer between workstations.Q: What is the maintenance process for this paddle mixer?

A: Maintenance is straightforward: the mixer features easily accessible components and a polished, rust-resistant surface for quick cleaning. Regular checks of the lid lock, overload protection, and seals are recommended to ensure ongoing safe and efficient operation.Q: How does the safety system benefit the operator?

A: The safety lock lid prevents accidental opening during operation, and overload protection ensures the mixer automatically halts if overloaded, safeguarding both operator and equipment from harm.Q: What are the main benefits of using this paddle mixer?

A: You benefit from high-efficiency, uniform mixing, robust construction, hygiene due to stainless steel surfaces, easy mobility, low operating noise, comprehensive safety features, and minimal maintenance requirements.

Price 300000.0 INR/ Piece

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 7-20 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mixing Equipments Category

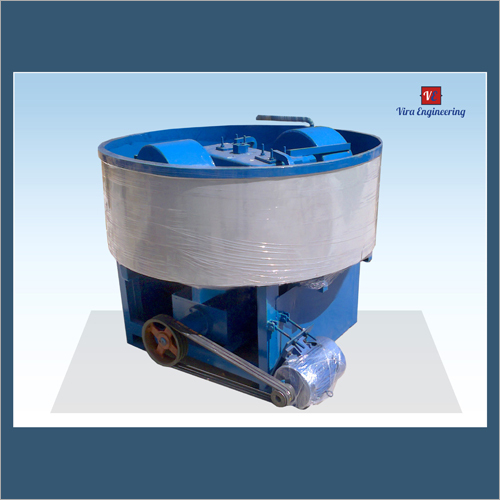

Counter Current Mixer

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Other, Horizontal Mixer

Capacity : 1500 liters/batch

Voltage : 415V (Three Phase)

Control System : Other, PLC Based Control Panel

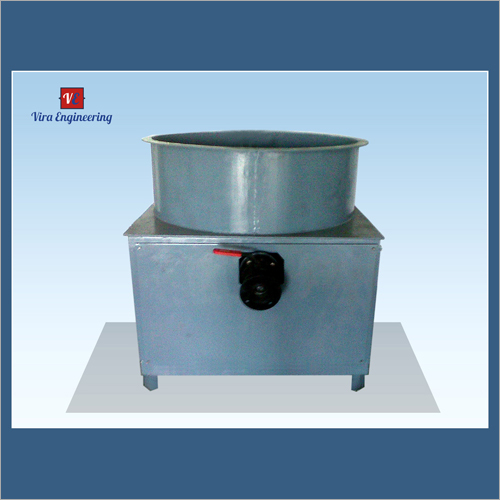

Muller Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Other, Horizontal Blender

Capacity : 100 Kg to 2000 Kg per batch

Voltage : 415 V

Control System : Other, Manual / PLC Based

Pan Mixer

Price 300000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Other, Batch Type

Capacity : 500 Liters

Voltage : 415 V AC, 3 Phase

Control System : Other, Manual/Starter Panel

Ribbon Blender

Price 400000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Other, Horizontal Blender

Capacity : 200 1000 kg per batch

Voltage : 415 V

Control System : Other, PLC or Panel Operated

Send Inquiry

Send Inquiry Send SMS

Send SMS